Knife sharpener purchasing advice: how to choose the right product

- The most important facts in brief

- Manual and electric knife sharpeners sharpen knives faster than whetstones.

- Because of the different sharpening angle, Asian knives need different knife sharpeners than European knives.

- For Asian kitchen knives with a one-sided grind, there is the smallest selection of sharpeners.

- The grinding material must be harder than the blade to sharpen it effectively.

- Models with three sharpening levels not only give kitchen knives a coarse and fine grind, but also polish them.

Knife sharpening simple and effective

If a knife squeezes the tomato more than it cuts it, it is dull. You can throw it away and replace it with a new one, but at least fine kitchen knives are too bad for that. It is not even necessary to throw away dull knives: A knife sharpener will make them as sharp as when you bought them.

When a knife is sharpened, the blade material is removed at a specific angle in a controlled manner. This restores the edge to its original shape and sharpness. How often a knife needs to be sharpened depends on the one hand on its material and grind, and on the other hand on how often it is used: if you handle the knife carefully and hardly ever use it, you will rarely need to sharpen it.

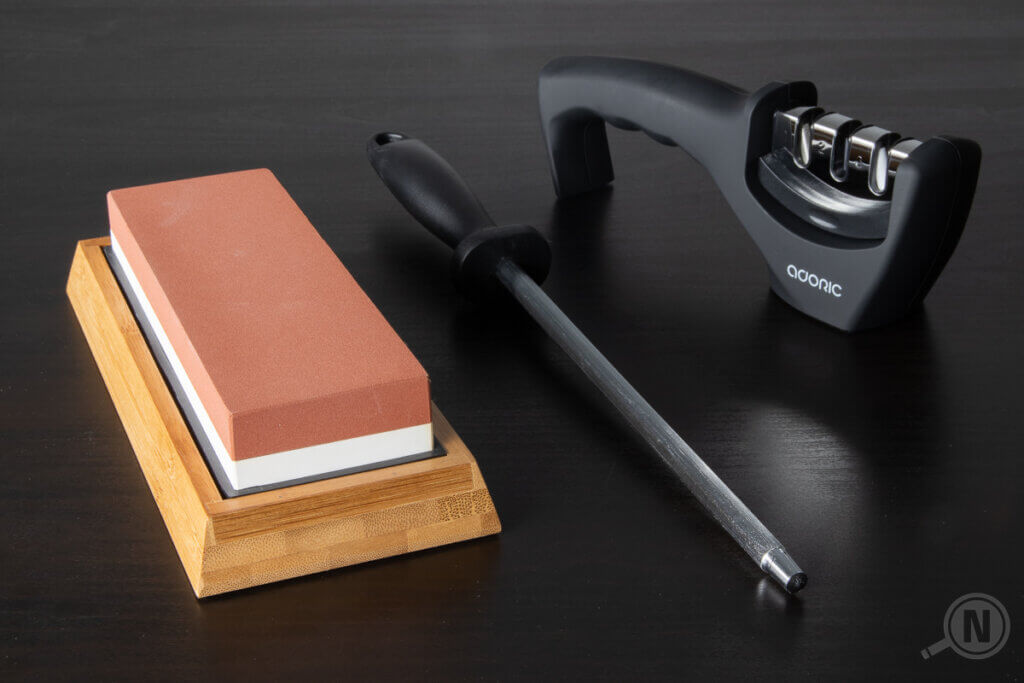

Professional knife sharpeners have perfected sharpening with whetstones and achieve excellent results: They know exactly how to hold a knife and move it over the whetstone. However, knife sharpening is easier with knife sharpeners. As they do not require any special knowledge, they are well suited for beginners.

Manual and electric knife sharpeners

The majority of manual sharpeners are pull-through sharpeners. Many models consist of a housing with one or more slots for the blade. The slots ensure that the blade is guided over the sharpening material at the correct angle. These are often several movable rollers or fixed discs, some of which have different grit sizes. In addition, there are variants in which two sharpening rods are spring-mounted in a V-shape on a holder. In addition to manual knife sharpeners, electrically operated versions are also available.

Pull-through grinder with immovable grinding material

Users have to pull the blunted knife through the opening once or several times, depending on the product. Sharpening is done by the movement of the knife alone, the abrasive material is firmly seated. The sharpeners are equipped with carbide plates or discs, with non-rotating ceramic and diamond rollers and with sharpening rods. Models with V-shaped positioned, often spring-loaded sharpening rods are also included, as they only spring slightly outwards, but are rigid at the holder.

Pull-through grinders with movable grinding rollers

With these pull-through grinders, you pull the knife through two ceramic or diamond grinding rollers that run at an angle to match the grinding angle. The movement of the knife causes the rollers to start rotating. With so-called water grinders, you fill water into the integrated container so that the underside of the grinding wheels comes into contact with the water. During the sharpening process, the rollers are continuously moistened by the rotation and remain clean. The blade is sharpened gently and effectively.

Electric knife sharpener

Electric knife sharpeners differ from manual pull-through sharpeners in the integrated electric motor and the mains connection, but hardly in the application. With these models, too, you pull the knives through one or more guide slots, with the difference that the motor sets the rollers or discs in motion. The sharpening result is good. However, as the removal rate is much higher than with pull-through sharpeners, you can damage the blade if you do not pull the knife through at a constant speed.

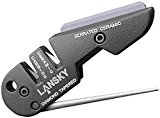

V-sharpener

A V-sharpener consists of a rectangular stand block that acts as a holder for various sharpening rods. The holder allows positioning at several grinding angles. Typical examples are the Spyderco Sharpmaker or the Lansky Crock Stick. The Crock Stick, for example, allows coarse and fine grinding at two sharpening angles. To sharpen, you run your knife several times from top to bottom along the respective sharpening rods.

Roll grinder

A special variant is the cylindrical roller grinder, each side of which is fitted with a whetstone. As with the Lansky sanding system, you move the sanding material along the blade: first the diamond side for rough sanding and then the ceramic side for fine sanding. Instead of a grinding rail, there is a magnetic base in the scope of delivery that fixes the knife at a 10- or 15-degree angle as required.

Other alternatives to the knife sharpener

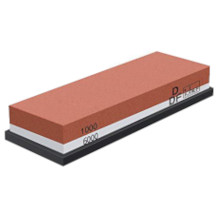

Grinding stones have been used for centuries. Nowadays, they usually consist of basic stones with abrasive grains made of materials such as ceramic, corundum or diamond and a binder such as synthetic resin. Depending on the grain, i.e. the size of the grains used, the whetstone removes more or less material from the knife.

To get a completely dull knife sharp again, you need a stone with a grit of less than 500 for the preliminary sharpening, a model with at least 800 for the main sharpening and a version with a grit of about 2,000 for resharpening.

Conventional sharpening steels do not sharpen in the true sense, they only straighten them. Therefore, sharpening rods serve more to preserve the blades. Only models made of ceramic or diamond sharpen the blades. Strictly speaking, however, these are not sharpening steels, but grinding or sharpening rods.

Storage and sharpening at the same time

Ordinary knife blocks are only used to store the set of knives supplied. However, the manufacturer Zwilling created a self-sharpening knife block called SharpBlock: two ceramic sharpening stones sit in the slots of the knives with smooth blades at a sharpening angle adjusted to the knives. The way it works is similar to that of a pull-through grinder. You sharpen the knives automatically before and after each use.

Important things to know when buying

Choosing the right knife sharpener basically depends on two factors: the knives you want to sharpen and the material you need for sharpening.

The knife properties

The material and its processing, the blade shape and size as well as the grind of the knives determine whether they will regain their sharpness with the knife sharpener or whether they will even be damaged. The origin of the knives or the manufacturing process is the most important feature. Knife sharpeners are mainly designed for European knives with a double-edged edge. As long as the blade width is not larger than the intended opening of the sharpening system, a European-style knife can be sharpened. With Asian models, choosing the right knife sharpener is more complicated.

Knife sharpener for Japanese knives?

Japanese knives have a very good reputation: they are very hard, have a high-quality finish and are incredibly sharp. Their cutting angle of about 15 degrees is less than the 20 to 30 degrees of European knives. In addition, many Japanese knives are only ground on one side. Both the hardness and the angle ensure that the knives are more sensitive and tend to break if handled incorrectly. For sharpening, therefore, wet sharpening stones are mainly used, as they are particularly gentle on the blades.

Many manual and electric knife sharpeners are too abrasive for Japanese knives. If you do not want to damage the knives irreparably, it is important to avoid unsuitable models. If you prefer to use a knife sharpener, you should make sure that it can be set to a grinding angle of 15 degrees and that it can handle one-sided grinding. This can be achieved, for example, with a roller grinder with a suitable grinding gauge.

Also suitable for serrated knives?

Knife sharpening is also relevant in another aspect. With a few exceptions, knife sharpeners only sharpen blades with a smooth grind, not with a serrated grind. Serrated knives can be recognised by their serrated edge. They are designed for cutting food with a hard exterior and soft interior, such as bread. Thanks to the teeth, you need to apply less pressure to cut a food. With the 1520 Electric Diamond Knife Sharpener, for example, Chef’s Choice offers a model that can be used with both smooth and serrated knives.

Grinding material

The prerequisite for any abrasive material used is adequate hardness: if the material is softer than the knife to be sharpened, it will not achieve the desired sharpening effect. In this case, the abrasive material will remove more material than the knife to be sharpened. If you want to sharpen a ceramic knife, for example, metal rods or plates are unsuitable. Instead, you need knife sharpeners that grind with ceramic or diamond, as only these materials are hard enough.

Inexpensive pull-through knife sharpeners often have carbide plates, which sharpen the blade initially but damage it badly over time. The more often the knife sharpener is used, the more bumps and bulges develop. High-quality knife sharpeners use tungsten steel, diamond and ceramics, for example. These sharpen the blades without destroying them in the long run.

Sharpening steps

Knife sharpeners, whether manual or electric, have several stages, sometimes called phases, depending on the model. For each stage, there is a separate opening in the housing into which you insert the knife. Some models, such as the manual knife sharpener from MYVIT, use a different grinding material for each stage: tungsten steel for coarse grinding, diamond for fine grinding and ceramic for polishing or honing.

It is advisable to use a knife sharpener that allows at least a coarse and a fine grind. The coarse grind or pre-grind removes the most material and can thus repair deep nicks. Some manufacturers also promise that they can rework the 20-degree sanding angle of European models to a 15-degree angle. Fine grinding is used to actually sharpen the blades. A third stage for polishing is practical, but not absolutely necessary. However, the result is cleaner and longer lasting with a resharpening.

A single-stage model is suitable for those who do not value a perfect result and only want to keep their sometimes inexpensive cutting tools in working order.

Determine knife sharpness with the tomato test

With the tomato test you can find out the sharpness of a knife blade. For the test, place the tomato on a work surface and gently apply the knife blade. Now move the knife over the vegetable without applying any pressure. If the knife cuts the tomato, it is sharp enough. If not, you should sharpen it again.

The outer shape of the knife sharpener

In a pull-through knife sharpener with slots, you can only sharpen blades that fit into the openings in the housing. Blades with a thickness of four millimetres or more are sometimes not suitable for this design. If the manufacturer does not specify suitability in the product description of the pull-through knife sharpener, it is worth taking a look at customer reviews and questions, because in most cases you are not the only consumer asking the question.

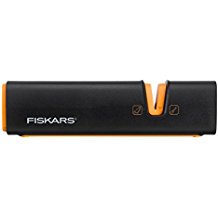

Knife sharpeners sometimes have very different overall sizes: Single-stage models in particular can have both a large height dimension, like the DMT Diamond Simple Sharp at 8.41 x 9.22 x 11.13 centimetres, and be flat and wide, like the Fiskar Roll-Sharp knife sharpener at 16.5 x 4.2 x 3.4 centimetres. Many tall V- or X-shaped knife sharpeners are also two-stage: the leading edge and the trailing edge are each used for coarse or fine sharpening. Multi-stage knife sharpeners often take up between 20 and 25 centimetres of space in length, and in manual versions part of this is part of the handle. In electric knife sharpeners, on the other hand, the motor is located at the point.

To sharpen effectively with knife sharpeners, they must have a stable stand. This applies to both electric and manual knife sharpeners. For this purpose, they are either large and heavy or have a handle. Suction cups are used with some products.

The right angle

Depending on whether it is a European or an Asian kitchen knife, different grinding angles are required. Typically 20 or 15 degrees, but some knives have also been sharpened at a different angle such as 16, 24 or 30 degrees. Accordingly, there are sharpeners that grind blades at these angles. Before buying, it is therefore important to compare the sharpening angle specifications of the device with your knives. Versions that have a grinding angle guide guarantee that you always work the knife at the specified angle. Grinders that allow you to adjust the sharpening angle are particularly practical. Even with some pull-through sharpeners such as the TANSUNG knife sharpener, this is possible by turning the wheel.

1,770 reviews

1,770 reviews