Meat grinder purchasing advice: how to choose the right product

- What You Need to Know

- In the past, a meat grinder was mainly used to make minced meat, but today it also grinds other foods such as vegetables and processes dough for shortbread, for example.

- If you use a rotary mincer, you can determine the freshness, mixing ratio, fat content and other qualitative aspects yourself.

- The food is filled into the meat grinder, transported to a knife via a screw conveyor and pressed out through a perforated disc at the end.

- There are manual meat grinders operated with a hand crank and electric meat grinders that are connected to a power source.

- As they process food, it is important that rotary grinders are cleaned roughly during prolonged use and thoroughly after use.

The meat grinder – a true all-rounder

In the past, the name said it all: a meat grinder was used to produce minced meat and sausage. This is still true, but today the device is moving away from being just a meat machine and is turning out to be a popular all-rounder. It functions as a multifunctional kitchen appliance in private kitchens as well as in the commercial sector.

What can a meat grinder be used for?

From mincing machine to all-purpose mincer: this is how the development of the meat grinder can be briefly described. In addition to various meats, such as sausage, the appliance now processes a variety of other foods, be it fish, vegetables or fruit, and supports the production of various dishes – from homemade pasta to shortbread. Therefore, the general name rotary mincer now fits much better. The possible uses are very diverse and offer room for creative ideas; for example, mincing chicken meat, which is not normally available in conventional supermarkets. For this reason, a meat grinder is also recommended for all hobby cooks who like to experiment.

The attachment makes the difference

Such a multi-faceted application requires several attachments. Not all foods can be processed with the standard attachment. Therefore, you should know in advance for which foods you want to use the kitchen appliance in order to choose the appropriate attachment.

Advantages of meat grinders

To illustrate the advantages of a meat grinder, let’s stick to the origin and explain them using minced meat as an example. If you love Bolognese, love burgers and adore the classic meatloaf, you can either get packaged meat from the supermarket or use a meat grinder to make your own minced meat. The second option has clear advantages:

- Focus on species-appropriate animal husbandry

- Own quality control

- Optimised taste

- Better consistency

The qualitative advantages – for example, control over species, origin, freshness and mixing ratio – are obvious and ultimately on the plate. But animal welfare can also be a consideration when consuming meat, because there are significant differences between meat from species-appropriate husbandry directly from the farmer and products from factory farming. If you want to pay attention to animal welfare, you can take the processing of meat into your own hands with a rotary mincer.

Construction and functioning of meat grinders

A meat grinder is used to mince food. The term is used mainly in Austrian and describes the process of turning something through the sausage machine; some also call it simply “spinning through” or “grinding through”. The process of grinding is very precise thanks to the different perforated discs and the different knife sizes.

Components of a meat grinder

Although there are different models of mincer, certain components are identical in all models:

- Filling device

- Feeding screw

- Knife

- Perforated disc

In classic models, you will find a hand crank that is attached to the appliance via a thread. The device for filling food is either in the form of a funnel or a bowl with an opening. There are often fastening rings on the perforated discs for fixing.

How does a meat grinder work?

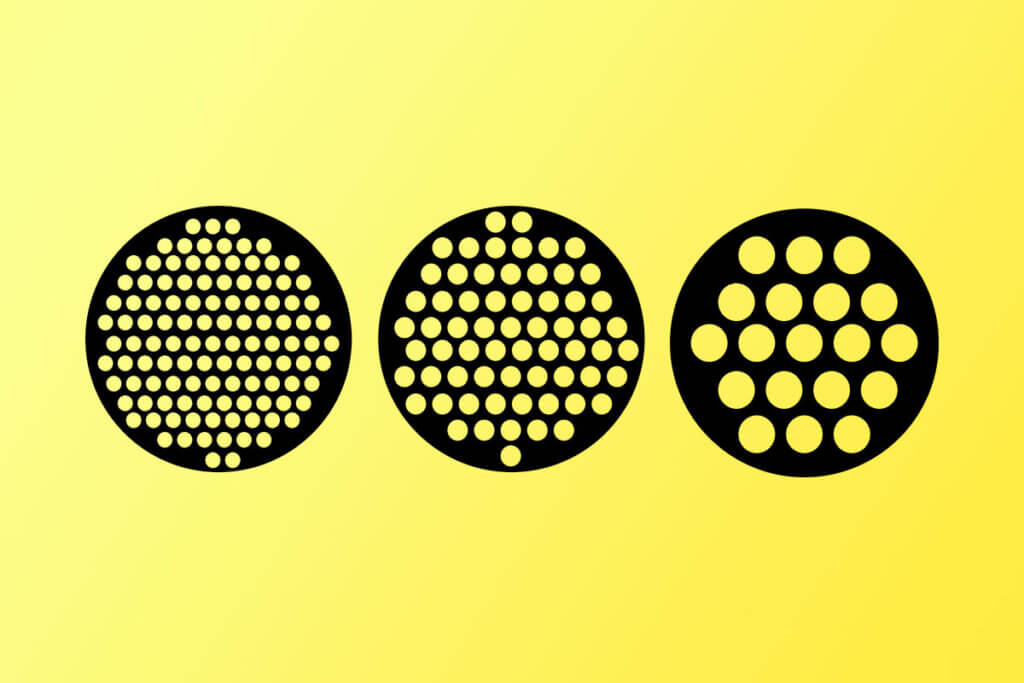

A meat grinder is not a complicated construction. The food enters the housing of the machine via the top-mounted feed device. The heart is called the auger, which is either manually or electrically operated. Here, the ingredients to be minced are transported towards the knife and perforated disc, partly mixed together and squashed a little. Finally, the main crushing process takes place. The food that reaches the end of the screw conveyor is very precisely chopped by blades – in some models first with a pre-cutting knife and finally with a knife that usually has four blades. The food is pressed out of the unit through the perforated disc – the smaller the holes on the disc, which is comparable to a sieve, the finer the result. Many models have a return mechanism to prevent blockages.

Cut small before shredding

What sounds contradictory at first is recommended, however: before you process beef into minced meat, for example, you should cut it into cubes by hand – this makes the meat grinder’s work easier, optimises the result and simplifies the application when you feed in the pieces. With meat, it is also important to remove all bones beforehand.

Safety first

A rotary mincer works with very sharp blades to cut up the food and not to crush it. Therefore, it is important that the meat grinder is always stable during operation. If the device wobbles or slips, a manually operated version in particular can quickly pose a safety risk. For this reason, clamp such models to the edge of the table with an appropriate device. Make sure that the meat grinder is always clamped as tightly as possible. Mechanical models, on the other hand, stand on suction or rubber feet. Here it is particularly important that the appliances have a secure and stable stand.

Do not push the food with your fingers and do not remove any leftovers from the inside when the meat grinder is in operation. Also, do not wear anything that can get into the feed opening and get caught in the machine – for example, a tie or a long chain.

Protect children

As a general rule, a meat grinder should always be stored in such a way that children cannot reach it. Since the blades are particularly sharp and the machines have a high dead weight of around six to twelve kilograms, there are considerable safety risks here.

What is the significance of the size specifications?

If you are considering a rotary mincer, you may stumble across numbers in the product description or in the title. These are the size specifications of the meat grinder. The numbers provide information on the diameter of the housing, the perforated disc, the centre hole in the perforated disc and the blade, as well as the width of the perforated disc and the blade. The numbers are therefore crucial when you want to buy a meat grinder, because the sizes of additionally or subsequently purchased parts are based on them. For accessories and spare parts, you should therefore pay attention to the size specification of your appliance – this is the only way you can be sure that the parts fit together.

Diameter of the housing

Sizes “10” and above are usually for gastronomic or industrial machines, while the specifications “5” and “8” are normally relevant for private households.

| Size specification | Diameter |

|---|---|

| 5 | 5.40 cm |

| 8 | 6.35 cm |

| 10 | 6.99 cm |

| 22 | 8.26 cm |

| 32 | 9.84 cm |

Size specifications of the perforated disc

Manufacturers continue to give numbers that refer to the perforated disc. The diameter of the meat grinder should match the size of the perforated disc. Three areas play a role here: the diameter of the perforated disc and the centre hole as well as the thickness of the perforated disc.

| Size specification | Diameter of the perforated disc | Diameter of the centre hole | Thickness of the perforated disc |

|---|---|---|---|

| 5 | 53.2 mm | 8.2 mm | 5.6 mm |

| 8 | 61.3 mm | 9.3 mm | 6.8 mm |

| 10 | 69.5 mm | 10.2 mm | 8.2 mm |

| 22 | 82.5 mm | 11.4 mm | 9.6 mm |

| 32 | 99.5 mm | 13.4 mm | 9.5 mm |

Size specifications of the knife

In the case of knives that are usually four-jointed, the specifications refer to the diameter of the knife as well as the width of the square centre hole.

| Size specification | Diameter of the knife | Width of the centre hole |

|---|---|---|

| 5 | 46.0 mm | 9.4 mm |

| 8 | 55.5 mm | 10.7 mm |

| 10 | 61.0 mm | 12.2 mm |

| 22 | 72.6 mm | 13.3 mm |

| 32 | 90.0 mm | 15.1 mm |

The larger the meat grinder, the larger quantities of food you can process at the same time. However, this does not mean that large products are always the better choice. After all, they take up more space, which is why occasional users in particular should think about buying a smaller model.

The old “7”

You may come across the size specification 7 on very old models, mostly handhelds. In this case, the following sizes apply to the perforated discs: 58.7 millimetres (diameter of the perforated disc), 8.2 millimetres (diameter of the centre hole) and 5.9 millimetres (thickness of the perforated disc). The knife sizes for the indication “7” are: 51.8 millimetres (diameter of the knife) and 9.4 millimetres (width of the centre hole). The dimensions are therefore between sizes 5 and 8. Usually, these perforated discs and knives can be combined with a size 8 meat grinder.

What types of meat grinders are there?

There are two basic types: the manual and the electric meat grinder. This reflects the technical development of rotary mincers, as the classic variant was and still is 0per manual operation. Today, electric devices are often available in private kitchens as well as in restaurants and butcher’s shops. In principle, the more often and the more you want to produce with as little effort as possible, the more likely it is that an electric meat grinder will fit into your household.

Manual meat grinder

Is the manual meat grinder automatically inferior to electrically operated machines? The answer is “no”. Manual mincers are still made – then as now, they deliver good end products and serve their purpose. A manual meat grinder is usually clamped to the edge of the table and operated by hand with a crank. The fact that you set the rhythm yourself gives the minced meat a particularly fine quality.

Advantages and disadvantages

Hand-operated models are cheaper and often quieter during operation. Since they do not require electricity, you do not have to expect additional electricity costs. To keep the mincing process going, the crank has to be turned permanently – this costs power in the long run and takes more time. Attaching it to the edge of a table or worktop is also more cumbersome compared to a standing unit. In addition, the devices are usually less flexible, as solid foods cannot be processed as easily.

Pro points

- Lower price

- No electricity required

- Mostly quiet operation

Drawbacks

- More force required

- More time needed

- Cumbersome fixation

- Fewer options

If you operate a manual meat grinder, you should be sure that the appliance stands solidly. Since you need both hands to put the food into the feed opening and operate the crank at the same time, you cannot hold the kitchen appliance while doing so.

Electric meat grinder

Without question, the electric meat grinder is much more advanced. Although manual versions are still available, the range of electric appliances is much wider. Such models usually stand on four feet and are connected to a power source via a plug to provide energy for operation.

Advantages and disadvantages

he electric meat grinder does the actual work alone, as you activate the grinding by pressing a button. This means that hardly any effort is required; moreover, the efficiency is optimised because the electric device processes larger quantities more quickly. Stringy meat and firmer foods can also be minced easily. During operation, the “e-shredder” usually stands stably on four feet. However, you have to dig deeper into your wallet for an electric rotary mincer and some motors operate very loudly. In addition, such a model represents another electrical appliance in your household, which entails corresponding electricity costs.

Pro points

- Less effort required

- High time saving

- Stable stand

- Many possibilities

Drawbacks

- Higher price

- Power supply necessary

- Often noisy operation

While electric models are inherently more solid, safety comes first here too. As soon as a product uses electricity, the usual safety measures for handling electrical appliances are required to avoid short circuits and possible electric shocks.

What to look for when buying a meat grinder?

Besides the type of meat grinder – manual versus electric – the following criteria play a decisive role when you are interested in a rotary grinder: Performance, functions, accessories and material. Initially, it does not matter whether it is a low-priced hand-crank device or a high-priced model with a motor.

Well-known brands: Aicok | Propower | Bosch | Kenwood

Power

The power is given in watts and is only relevant in the context of electric meat grinders. Particularly powerful models have up to 2,000 watts, while weaker devices are around 250 watts. The motor power has a significant influence on the amount of processing: a meat grinder with a higher wattage can process more food in the same amount of time compared to a less powerful device. In addition, a more powerful motor can usually grind harder foods such as nuts better.

Functions and accessories

If you are only looking for a mincing machine, you do not need an appliance with a wide range of functions. But there are models that impress with their multifunctionality – from preparing meat to shredding vegetables. Special attachments for piping pastry, for example, can be used to shape dough. The attachment for stuffing sausages is considered particularly practical for friends of roast sausages and other homemade sausage. A kibbeh attachment can be used to make the filling for the Arabic dish kibbeh.

In addition, special knives are included in the scope of delivery of some appliances; for example, blades with two knives and straight or curved blade blades. The more variably the rotary mincer can be equipped, the more preparation options you have. You can conveniently place the food on a filling tray at the top opening. A tamper helps you fill the ingredients and increases safety because you don’t have to push with your fingers.

From standard to set

In most cases, both electric and manual appliances come as well-equipped sets that offer more than two perforated discs for coarse and finer results. In addition, the sets often include various attachments and different blades to convert the machines accordingly.

Material

Manual meat grinders used to be made of steel, whereas most of today’s meat grinders are mainly made of stainless steel – stainless steel, in contrast to pure steel, is durable and looks modern, stylish as well as high-quality. If you don’t use the meat grinder often, you can go for a lower-quality device made of plastic with a clear conscience. Models made of cast steel, usually the manual mincers, score with their robustness and original charm. Particularly extravagant appliances are made of ceramic.

How can a meat grinder be cleaned?

Cleaning should be done roughly in between and very thoroughly after the grinding process. If you use the grinder several times in a row, it is important to remove residues from all areas after each step – you can use a small brush or cloth for this. Without this rough cleaning, you would, for example, be working with dirty knives that no longer achieve their full cutting performance and are unhygienic. If you change from meat to vegetables or dough, for example, you should also make sure to clean thoroughly beforehand so as not to mix different foods.

Finally, the entire appliance should be cleaned thoroughly with hot water and optionally with washing-up liquid to remove grease and stubborn dirt as well as to prevent the formation of mould and germs. For thorough cleaning, you must disassemble the appliance and clean the elements individually. A meat grinder that can be disassembled without additional equipment is therefore particularly practical. Cleaning is simplified if the individual parts of the meat grinder are dishwasher-safe.

Good cleaning always includes thorough drying. This reduces the likelihood of limescale deposits. Dry the disassembled elements with a towel and simply leave them overnight.

no reviews

no reviews