Cordless rotary hammer purchasing advice: how to choose the right product

- The most important in a nutshell

- A hammer drill is used where conventional drills can no longer go.

- Use a hammer drill to work on solid materials such as concrete and stone.

- Cordless hammer drills can be used flexibly, independent of a power source.

- The impact strength in joules reveals how much power the machine has.

The specialist for heavy tasks

Electric tools such as cordless drills and impact drills are part of the basic equipment of well-equipped do-it-yourselfers. The hammer drill, on the other hand, is rarely found in hobby workshops, which is not surprising, because the powerhouse that effortlessly drills through stone and concrete commands some respect.

While a percussion drill is capable of drilling holes in solid materials such as aerated concrete and brick, at some point it will reach its limits. For solid materials, it’s time to use a hammer drill. Such a powerful drill will cope even with concrete and granite. The hammer drill is also the tool of choice for caulking work such as wall penetrations.

Many electric tools are available as cordless devices with rechargeable batteries – including hammer drills. Cordless hammer drills offer significantly greater flexibility of use than corded models. This is helpful if, for example, no power outlet is accessible at the construction site. Although battery-powered devices are more mobile than conventional hammer drills, users usually have to accept sacrifices in puntco performance.

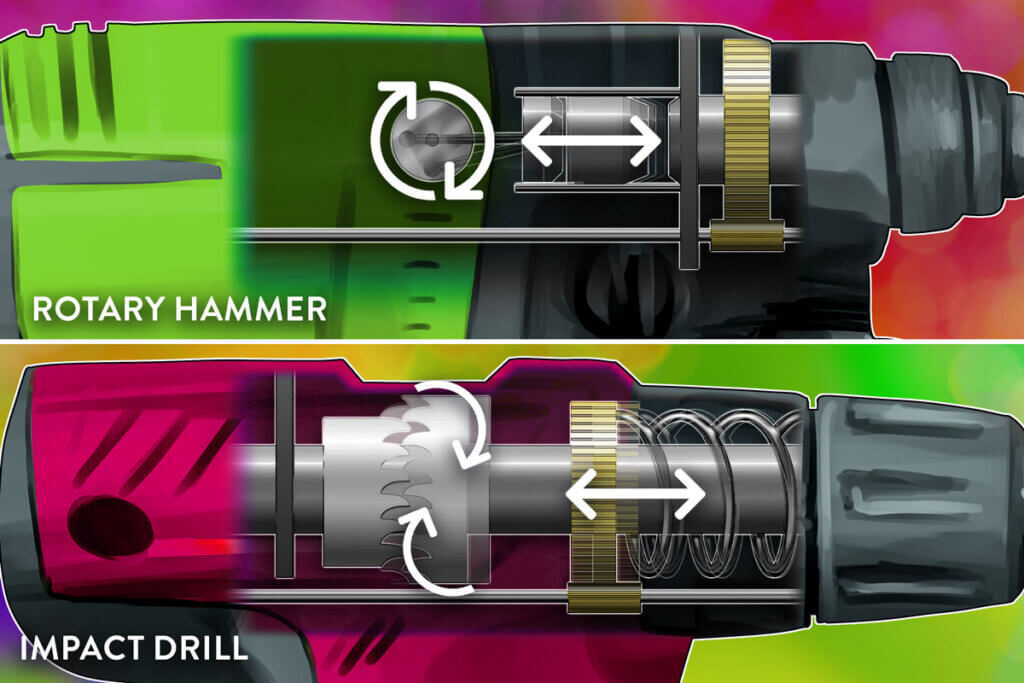

The difference between hammer drill and impact drill

The difference in these two electric tools lies in the type of striking mechanism. A percussion drill has a mechanical percussion mechanism that produces a vibration – the impact. This can be switched on and off. If the impact is deactivated, the impact drill can be used as a classic drill. When drilling in hard materials, the impact must be added. Since the percussion drill does not have its own propulsion, this must be provided by the user. At the same time, he or she must resist the backlash. So, working hard materials with the impact drill is possible, but extremely energy-consuming.

Unlike the impact drill, the cordless hammer drill is equipped with an electropneumatic impact mechanism. Impact energy is generated by an interplay of negative and positive pressure. The pneumatic percussion unit essentially consists of four components: Pistons, firing pins, beaters and drive bearings.

The drive bearing absorbs the rotational movement generated by the electric motor, which in turn is converted into a stroke movement by the piston. As the piston moves backward, a vacuum is created that pulls the beater backward. During forward motion, on the other hand, excess pressure occurs between the piston and the beater. The two components move forward at high speed and transfer the kinetic energy to the firing pin. Since the firing pin is responsible for transmitting the impulse, it must be made of extremely robust hardened steel.

This is what you should look for when buying a hammer drill

When choosing a hammer drill, the main thing is power. Important key figures for this are the impact strength as well as the impact and rotational speed. A cordless hammer drill must be equipped with a sufficiently powerful power source to provide the required power.

Impact strength

Which projects can be implemented with the electric tool depends on the impact strength. The higher this is, the harder the material to be machined can be. The joule number indicates the impact force of the hammer drill. If you want to use the tool mainly for simple drilling and chiselling work, you can get by with a machine with 1.5 to 3.5 joules of impact force. Such a hammer drill is a good all-rounder and is also suitable for heavier work in case of doubt.

An impact force of around five joules is required to remove tiles. When it comes to tearing down entire walls, a heavy piece of equipment is called for. Depending on the thickness of the wall, a hammer drill with well over ten jo ules is then required. Such a powerful machine is rather unsuitable for laymen.

Impact and speed

The impact and speed data provide important information on the efficiency of a hammer drill. For efficient work, it is advisable to drill at the highest possible speed, as the impact rate of a hammer drill is usually linked to the speed. In use, machines with a speed of around 900 revolutions per minute have proven themselves.

If you want to work as effectively as possible, you should also focus on a high stroke rate. However, a high stroke rate is not the best, because the strokes are more frequent, but with less force. Do-it-yourselfers should choose a machine with 4,000 to 4,500 strokes per minute.

Battery power

The quality of the battery is particularly important for a cordless hammer drill. A modern power tool should be equipped with a lithium-ionbattery. This does not suffer from the so-called memory effect, which permanently damages a battery if it is charged at the wrong intervals.

The battery capacity in ampere-hours is important for estimating how long you can work with the tool without having to recharge it. Professional versions have efficient batteries with at least four amp-hours. DIY enthusiasts will probably also be satisfied with a slightly weaker battery of two amp-hours.

Most cordless hammer drills have a voltage of 18 volts. The higher the volt number, the stronger the battery. At a voltage of 18 volts, the energy potential of a hammer drill is well exploited. Professional machines are sometimes even equipped with 36-volt batteries.

When it comes to charging time, cordless hammers are sometimes far apart. Some fast-charging devices require only 30 to 60 minutes for a full charge. Others are only fully operational again after three hours. Those who work often and intensively with the tool should pay attention to a short charging time.

Anti-vibration technology

When working with power-driven tools, users are always exposed to vibrations. Vibrations are mechanical shocks that are transmitted to the human body through direct contact. Being permanently exposed to vibrations can have serious consequences for health. Effects of hand-arm vibration include the following:

- Stiff fingers

- Decrease in skill

- Damage to vessels and nerves

- Impairment of the sense of touch

- Damage to bones and joints

The Noise and Vibration Occupational Health and Safety Ordinance defines limit values for hand-arm vibrations during an eight-hour working day:

- Exposure limit: A(8) = 5 meters per square second

- Trigger value: A(8) = 2.5 meters per square second

If the exposure level is reached, there is a high health risk. Work must be interrupted and measures taken to fall below. If it is not reached, but the action value is exceeded, the risk is in the medium range. The trigger threshold is the measured value above which vibration reduction measures must be taken. If the measured value is lower than this, only normal precautionary measures should be observed.

To protect users from vibrations, cordless hammer drills are usually equipped with more or less sophisticated anti-vibrationtechnologies. Vibration values can be reduced to a minimum by means of a built-in counter-vibrator in the gearbox. Such a hammer drill is also extremely comfortable to guide. A common vibration damping measure is spring-loaded handles that absorb the vibrations.

Device weight and operability

In terms of working comfort, the weight of a hammer drill plays an important role. The very powerful devices are usually quite heavy, weighing three to four kilograms . Especially professionals rely on these heavy machines. Weaker models for simple work are considerably lighter at just under two kilograms.

A heavy tool like a hammer drill should be as comfortable as possible in the hands. Make sure that the machine is equipped with so-called softgrip handles. These enable particularly pleasant handling. All functions of the hammer drill should be easy to reach and change – even during use.

It is particularly practical if the various drills can be changed in just a few steps and, above all, without tools. SDS-Plus shank systems allow easy accommodation of various drills and chisels. Quick-action drill chuck enables quick change of attachments. Such a drill chuck is also operated without tools.

This is how loud hammer drills are

Noise is stress and has a negative impact on health. Unfortunately, this is always to be expected when working with power-driven machines – and hammer drills are really loud. Many models reach more than 90 decibels in operation. This makes them about as loud as a circular saw. It is therefore essential to wear hearing protection when working with a hammer drill.

Useful accessories

Most DIYers can probably get by with the universal drill. These are capable of machining wood, metal, plastic and masonry. Special drills are needed for more specialized projects. The masonry drill is suitable, for example, for natural stone, limestone and brick. For hard concrete, the hammer drill is used. The tile drill breaks through the glaze of tiles effortlessly.

The same applies to chisels, which are suitable for different purposes depending on their nature. The pointed chisel allows precise work. The spade chisel can be used to break off larger areas. Use the tile chisel to lift tiles from the wall.

So-called chisel grease is used to minimize friction between the shank and the chuck. This has a positive effect on the longevity of the device. Professional machines are in most cases equipped with a built-in lubricator that automatically applies the grease. If this is not available, it must be applied by hand after about every third or fourth use.

A depth stop ensures that holes of the same depth are always drilled. This is a metal rod that is threaded on the front handle and fixed with a set screw. The stop hits the wall after a number of centimeters set before drilling and prevents deeper penetration. All holes are exactly the same depth at the end.

If you choose a cordless hammer drill, it makes sense to have an exchangeablebattery with you. With a second battery in the luggage, it is always ready for use and the work succeeds without annoying forced breaks. Most manufacturers rely on their own battery system. Within their own series, batteries can be used for several devices – but not so for devices from other manufacturers. So it can make sense to go with a single manufacturer for power tools.

Choosing the right drill

To choose the right drill for your project, you need to know which drill is suitable for which material. With wallpapered walls is not immediately apparent what kind of material it is. The knock test quickly tells you whether the wall is solid concrete or stone, or lighter material such as sheetrock.

Another way to determine the material is to examine the drilling dust. For this it is necessary to drill a hole on a trial basis. If the dust produced is red, the wall is made of bricks. If the dust is white, it is probably sand-lime brick. If the dust is gray, the wall is made of concrete.

Simpler tasks can usually be done well with the universal drill. It is designed to drill stone as well as wood and metal. While the universal drill is particularly versatile, it is not a substitute for a drill specifically designed for one material.

A masonry drill is made of particularly robust tool steel. It also copes with hard materials such as concrete, natural stone, tiles and even granite. A wedge-shaped metal plate is soldered to the tip of the drill, which shatters the substrate during drilling.

Wood is also excellent to drill with a hammer drill. Wood drills have a center point, which is used for precise alignment. The cutting edges of the wood drill are longer on the outside than on the inside edge. Thus, the edge of the drill hole is cut first and a clean hole without tearouts is created.

A metal drill is made of high-speed steel. The front of the drill is conical and has two sharp cutting edges. With such a tool can be drilled in iron, steel, copper, brass and aluminum. The metal drill is also suitable for drilling in plastic.

Besides the type of drill, its size also plays an important role. It must have a diameter that fits your project. This is particularly important if dowels or other connections are to be anchored in the drilled hole. To be on the safe side, a smaller drill bit is always selected first and then re-drilled with a larger one. Depending on the size of the screw that is to be anchored in the hole together with the dowel, the drill bit size is adjusted. In this way, incorrect drilling is avoided.

Occupational safety when using a hammer drill

A hammer drill is a powerful tool and should be used wisely. Basic protective equipment when working with a hammer drill includes hearing protection, safety glasses and suitable gloves. The gloves protect against bruising and against the heat that a hammer drill can develop. Since a lot of dust is generated when working with a hammer drill, wearing a respirator is also recommended at most. Safety shoes and a hard hat are also useful when demolishing tiles and walls.

Fig. 1: © Ralf Geithe / stock.adobe.com | Fig. 2: © Netzvergleich | Fig. 3: © PhotographyByMK / stock.adobe.com | Fig. 4: © Виталий Сова / stock.adobe.com

2,871 reviews

2,871 reviews