Random orbital sander purchasing advice: how to choose the right product

- What you need to know

- A random orbital sander can be used to treat wood, metal and plastic surfaces.

- An orbital sander masters uneven surfaces better than an orbital sander.

- Converted random orbital sanders are ideal for polishing paintwork.

- A low-vibration model is recommended for easy handling.

The versatile fine grinder

There are a number of devices for sanding wood surfaces, such as delta, angle or orbital sanders. The random orbital sander is used for all wooden objects that have curves and curves – that is, primarily for furniture. A random orbital sander is particularly good for finishing wood surfaces.

The term “eccentric” is derived from the Latin “ex centro”, which means “from the center”. In mechanical engineering, this is understood to mean a control disk mounted on a shaft, the center of which lies outside the shaft axis. The grinding wheel of an eccentricsander therefore performs eccentric movementsas it rotates.

Since an eccentric sander performs eccentric and rotating movements simultaneously, it achieves a very fine sanding pattern and can also be used for polishing. The typical grinding patterns that occur on the workpiece when using angle and orbital sanders are avoided in this way. For this reason, the random orbital sander is a very popular tool in the furniture industry, among others.

Advantages

- High material abrasion

- Ideal for fine grinding

- Working on uneven workpieces possible

- Convertible with special attachments

Disadvantages

- Grinding in corners not possible

Random orbital sander and orbital sander – what is the difference?

When processing wood, the orbital sander is often used in addition to the random orbital sander. This raises the question of what the differences are between the two devices and which is the right one for your project.

The base surfaces of the two grinding machines perform different movements – the abrasive grain is therefore moved over the workpiece in a different way. Because an eccentric oscillating motion is combined with a circular motion in an eccentric sander, no abrasive gritstays in one place longer. An orbital sander, on the other hand, performs only a circular oscillating motion and the abrasive grains move minimally. For this reason, it must be constantly moved by hand. Otherwise, visible curls would appear on the workpiece.

Due to the larger grinding plate, large surfaces can be processed more effectively with a random orbital sander than with an orbital sander. Moreover, the random orbital sander is ideal for curved and rounded surfaces. For small, rectangular workpieces, edges and corners, on the other hand, the orbital sander is the best choice. It is often recommended to use an orbital sander for rough preparatory work and a random orbital sander for fine sanding. Well-equipped DIYers have both devices in the workshop and are thus optimally equipped.

Important purchase criteria for random orbital sanders

A corded grinder is ideal for use in your own workshop. Pneumatic versions require a compressor to be put into operation. The power and the number of oscillations are decisive for the effectiveness of the random orbital sander.

Cable, battery or pneumatic?

When buying a random orbital sander, the first question that arises is the drive. There are three common methods, although the operation of the different models remains identical.

Corded random orbital sander

Random orbital sanders of conventional design are corded. They have a higher power than battery-powered models, as they draw power directly from the mains. Since there are no loading times, these designs are particularly well suited for processing larger areas. There are always power outlets in a workshop; therefore, corded random orbital sanders are the first choice for this environment. They are connected to the conventional 230-volt household socket.

Battery powered random orbital sander

If the random orbital sander is to be used on the move, the cable can become a nuisance. Battery-powered machines can be used independently of a power outlet. So if you often have to do work beyond your own workshop, you should go for a battery-powered model. However, battery-powered random orbital sanders offer significantly less power and the usage time is limited due to the limited battery capacity.

Pneumatic random orbital sander

Pneumatic random orbital sanders work with compressed air. They are ideal if the workshop already has a compressor. One is absolutely necessary for operation and must be purchased if not available. Air-powered random orbital sanders have a less complex structure than models with an electric motor. That is why they are usually cheaper. Pneumatic random orbital sanders work very effectively with little effort. Machines supplied with compressed air are characterized by particularly quiet operation.

Power

How powerful a random orbital sander is can be read from the wattage. However, this is often only specified for wired devices. Most corded random orbital sanders operate at 200 to 500 watts. To achieve good results, the grinder should be equipped with a power of at least 300 watts. However, high performance alone does not ensure a better result. Other factors play a role here, such as the vibration number.

For battery-powered random orbital sanders, often only the operating voltage is specified instead of the wattage. In most cases, this is between 12 and 20 volts. The performance of pressure-driven grinders is highly dependent on the compressor.

Grinding stroke

The grinding stroke refers to the stock removal rate of a random orbital sander. This varies from device to device. In the professional field, therefore, different machines are used depending on the application. Some professional random orbital sanders have a switchable stroke and are therefore particularly versatile.

Basically, the larger the grinding stroke, the higher the stock removal. High stock removal is accompanied by a coarse surface. A grinder with three millimeters of stroke is ideal for fine grinding. A medium grinding stroke of five to seven millimeters is well suited for preliminary and intermediate grinding. Everything above this is used for rough grinding.

Vibration number

In addition to the wattage, the oscillation rate is also an important indicator of the performance of a random orbital sander. Manufacturers usually specify them in revolutions per minute. With many revolutions per minute, the material abrasion is correspondingly high – the smoother the ground surface becomes. For most corded machines, the vibration rate is between 12,000 and 16,000 rpm. On battery models, on the other hand, it is only 7,000 to 12,000 revolutions. These specifications usually refer to idling. The actual speed during use is therefore lower. Random orbital sanders have a control on which the speed can be adjusted.

Grinding wheel size

The larger the grinding disc, the more surface can be machined with each revolution. The usual sizes for the grinding discs are 125 and 150 millimeters in diameter. Although the difference does not seem particularly large, it is clearly noticeable during grinding. Most craftsmen probably agree that sanding is not a very nice job – all the better if it is done quickly. This is best done with the larger 150-millimeter sanding disc. Roughly calculated, this has 44 percent more surface area than the smaller 125-millimeter sanding disc. A large grinding disc is also advantageous when working on uneven surfaces. The larger the plate, the less it follows irregularities on the workpiece. This makes it easier to level an uneven surface.

But the smaller 125-millimeter grinders also have their raison d’être. They can be used to work in a more targetedmanner. This is an advantage for all work that does not involve the quick sanding of large surfaces, such as furniture restoration. The compactness of the devices can also be an advantage. They are not only lighter, but also easier to reach hard-to-reach places.

Type of sandpaper

When choosing sandpaper, first pay attention to the color. The two common colors are light gray and ruby red. Sanding disc and sandpaper are usually connected by means of Velcro.

The ruby sandpaper is most often used. It has a closed grain, so they abrasive grains sit close together. This makes it suitable for sanding lacquers and wood.

Light gray sandpaper, on the other hand, has an open scatter. So there is a lot of space between the individual abrasive grains. This is ideal for sanding plastic, but also varnish.

Both colors of sandpaper are again available in different grits. The grain size refers to the size of the abrasive particles. The higher the number indicated, the finer the paper. The following table shows the most common grit sizes for sanding wood.

| Grinding pattern | Grain size |

| Very rough | 40s |

| Rough | 60s |

| Medium | 80s |

| Fine | 120s |

| Very fine | 180s |

| Extra fine | 240s |

When sanding wood is often worked in gradations. The coarse 80 grit sandpaper is used for initial sanding and removal of old paint. This paper leaves many grooves in the wood. Therefore, the workpiece is reworked with a finer paper, initially with 120 grit. The final step is a paper with 180 grit, which provides the finishing touch.

Vibration strength

All grinding machines vibrate during operation, which exposes the hand-arm system in particular to high loads. Therefore, you should choose a grinder that is as low vibration as possible. A simple solution to reduce vibrations is a second handle, which helps to control the device more easily. On some grinders, the drive shafts are equipped with rubber padding inside, which serves as a vibration dampener.

A more professional solution is the so-called autobalancer. This is a type of ball bearing that sits on the drive shaft of the grinding machine and therefore rotates as fast as the grinding wheel. During rotation, the balls generate a counterforce to the unbalance caused by the rotating disk. This unbalance, which leads to the unwanted vibrations, is compensated for by the autobalancer.

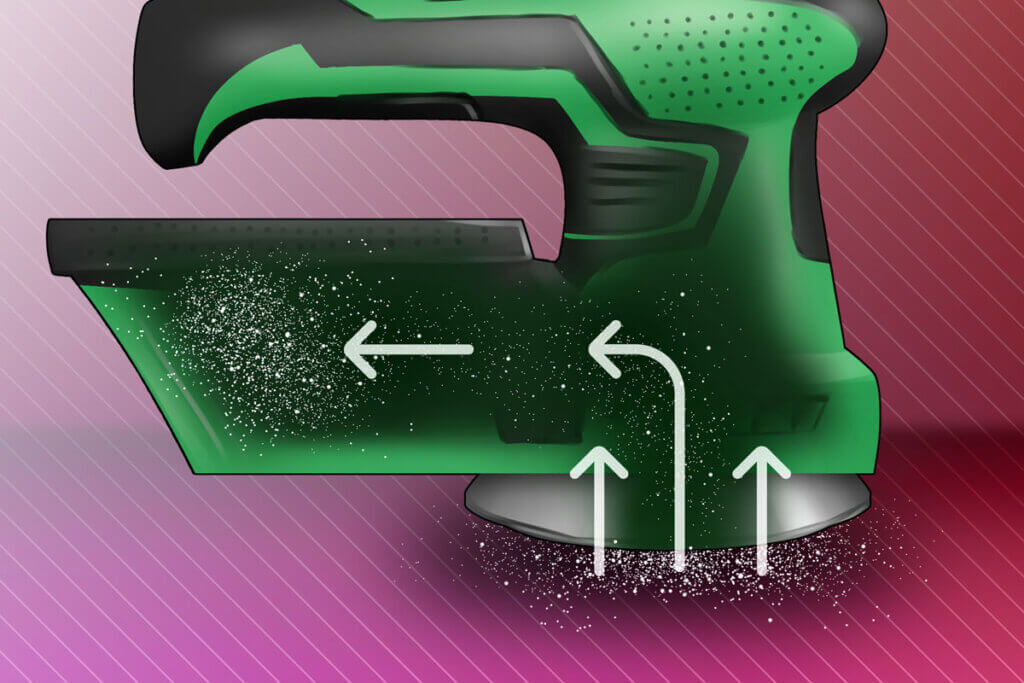

Dust extraction

For effective work with the random orbital sander, continuous extraction of the sanding dust is important. An extraction system is standard on random orbital sanders. When looking at the grinding plate from below, it is noticeable that there are several suction holes. The grinding wheels are also offered with the appropriate holes. The extracted dust is collected in an integrated container.

When working with the machine, the grinding wheel rotates at a high speed. This creates a negative pressure. Ambient air is drawn in via side vents. In this way, not only the motor is cooled, but also dust is sucked up and transported out of the grinder through the holes to the rear.

Many random orbital sanders have a dust collection bagbelow the rear handle. Some manufacturers rely on a solid dust collection box instead. Box or bag are able to absorb a certain amount of dust. They must be emptied regularly, for which it is necessary to interrupt the work. Often, the collection boxes are much easier to empty than the dust bags.

Where dust collector box or bag is connected, in many cases a vacuum cleanercan also be connected. This is the most professional and effective solution. If you are doing major work with the grinder, it is best to connect an industrial vacuum cleaner. For grinding work on a normal scale, a normal household vacuum cleaner is usually sufficient.

Fields of application of a random orbital sander

Unlike the classic orbital sander, a random orbital sander is versatile. While the main task of the orbital sander is limited to the processing of hard and soft wood, the random orbital sander is also used for materials such as glass and plastic.

Woodworking

Just like the orbital sander, the random orbital sander is also ideally suited for working on wood. Compared to other grinding machines, however, it has a decisive advantage: Due to its design, it is much easier to use on uneven surfaces. This is a real help when working on furniture or sanding door frames, for example.

Edit floor

Wood floors lose their luster over the years. A random orbital sander can be used to remove scratches and wood discoloration from parquet and floorboards. After that, the floor will appear as new. When sanding normally worn floor, the use of grit sizes 40, 80 and 120 should be sufficient.

Polishing

A random orbital sander offers the best conditions to be used as a polishing machine as well. The eccentric circular movements are particularly suitable for polishing and give a flawless shine to lacquered furniture or car bodies. Small scratches in the car paint can also be repaired by polishing. Of course, the grinding attachment must first be replaced with a special polishing attachment.

Grind varnish

There are several situations when it makes sense to sand the car paint. If superficial damage cannot be removed by polishing, the affected area can be sanded and then repainted.

Metal grinding

With the right attachments, a random orbital sander can also be used to finish or seal metal surfaces. For example, after removal of the weld seam on metal, the grinding marks can also be removed with the help of an eccentric grinder.

Safety instructions for use

Rotating tools such as random orbital sanders are always dangerous. To prevent the risk of clothing being caught by the device, tight-fitting work clothing should be worn if possible. For the same reason, it is advisable to wear T-shirts and shirts in pants at work. Since a rotating disc is used, it is not advisable to wear gloves.

One potential source of danger is slipping with the grinder on a moving workpiece. The object should therefore always be fixed so that it cannot slip. Furthermore, it is advisable not to exert too much pressure when grinding. Under no circumstances should the workpiece be held by hand only. Screw clamps, for example, are used for fixation. A random orbital sander with two handles provides additional grip and improved guidance.

For the protection of their own health is also important reliable dust extraction. A mouth guard and safety glasses are essential due to the dust generated. In addition, the ventilation slots of the grinding unit should be checked regularly for residues which could impair the suction function.

Image 1: © Georgiy / stock.adobe.com | Image 2: © tiero / stock.adobe.com | Image 3: © megaflopp / stock.adobe.com | Image 4: © FinalCheck | Image 5: © Ilya / stock.adobe.com

4,911 reviews

4,911 reviews