Scroll saw purchasing advice: how to choose the right product

- What you need to know

- Scroll saws are the electric version of fret saws.

- They are primarily intended for very delicate sawing work.

- Scroll saws can be used for many different materials.

- Working with scroll saws is extremely safe.

Filigree work with a scroll saw

A scroll saw is a practical electric tool that is mainly used in the hobby sector – for example for the following work:

- Manual cutting of any contours in thin material of all kinds

- Cutting profiles to length with high precision

- Producing any kind of shaped inlays or fitting pieces

Scroll saws in use

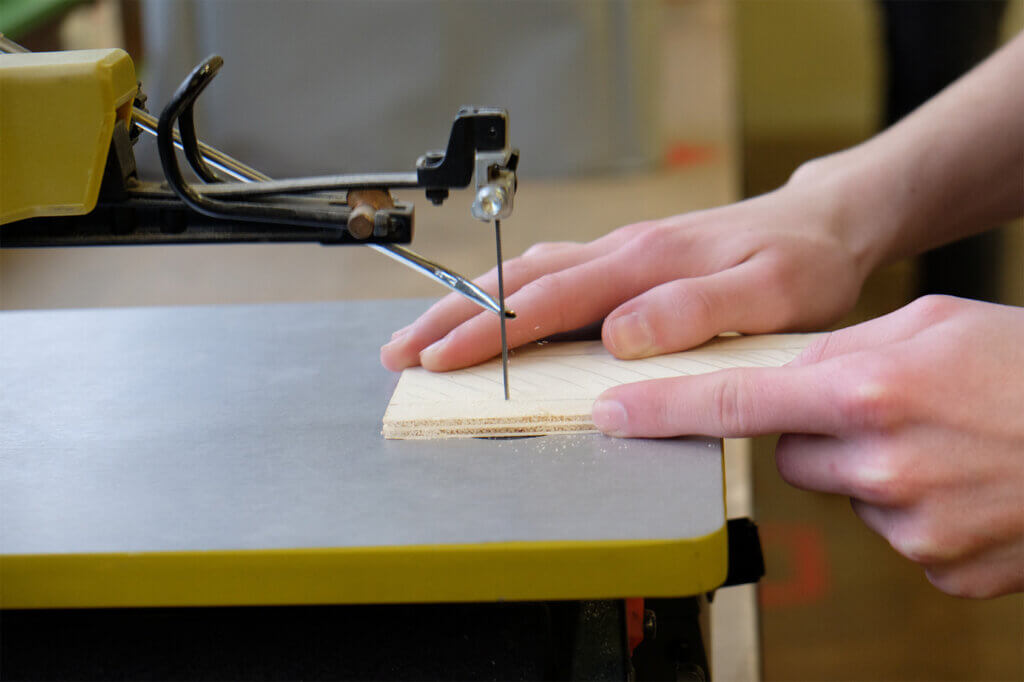

Although a scroll saw is powered by a motor, similar to a jigsaw, users must guide the workpiece by hand. It is extremely popular with hobbyists, model makers and makers. With its help, all kinds of thin materials can be prepared, made up, reworked or adapted to the project at hand.

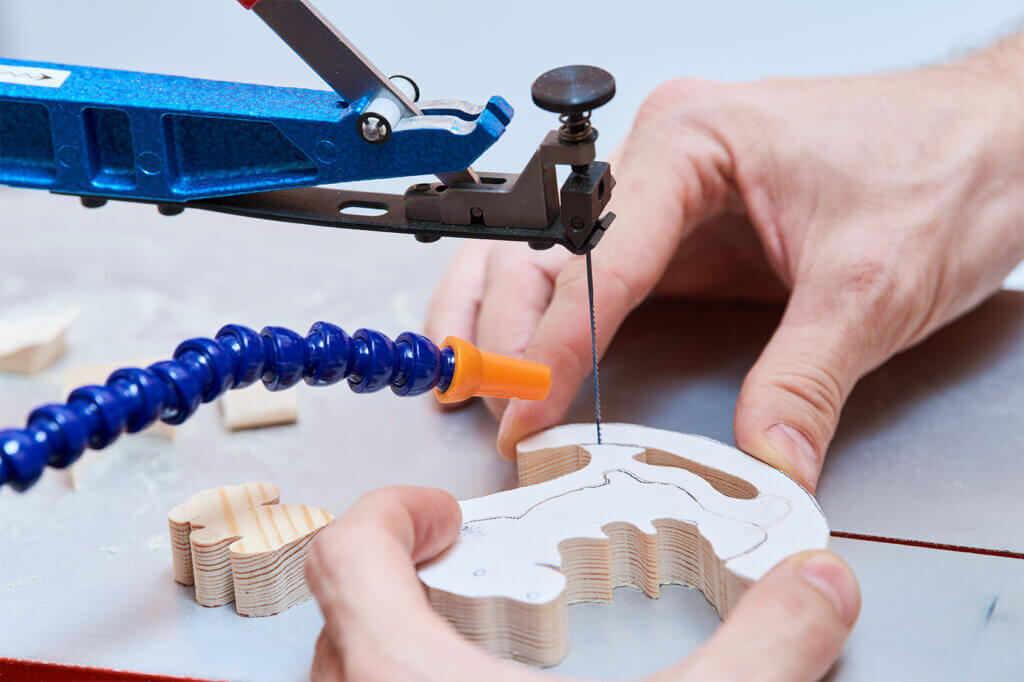

In the professional sector, a scroll saw can be found, among others, with tilers, piano makers, sheet metal workers and furniture makers. An additional drilling device is required for the internal cutting of thin materials. It provides the starting hole from which a scroll saw is used to saw out the desired recess. In this respect it is clearly superior to the small band saw: Threading the cutting wire through the drilled hole is much easier.

In addition to shapely ornaments, a scroll saw can also be used for high-precision cutting to length of mouldings, empty pipes made of PVC or other long materials. It can achieve solutions where a coping saw is too inflexible. In addition, a scroll saw can machine a workpiece from the inside out. This makes it particularly suitable for cutting filigree inlays in wooden panels. With the right saw blade, a scroll saw can also work on metallic or mineral materials, such as tiles. That is why it is the right tool, for example, to produce precisely fitting pieces along heating pipes or other complicated places.

The different types

Technically, scroll saws are all basically the same. The main differences are in the workmanship, the load capacity and, above all, the bow height. Scroll saws in the lower and middle price segments usually have a very low bow height. They can only be used to cut workpieces made of thin material, such as plywood panels, plastic sheets or tiles. Scroll saws with a large bow, on the other hand, can also be used for beams and squared timber. However, a lot of practice, experience and a particularly steady hand are required for the precise processing of thick materials. Large scroll saws are therefore mainly found in the higher price segment.

Construction and mode of operation

A scroll saw is primarily a tool for fine cutting. Although the standard material is plywood, plastic panels, aluminium sheets and panels made of composite material can be processed just as well on the scroll saw. On the other hand, it is less suitable for thicker beams and boards. Due to the flexibility of the cutting medium, the straightness of the cut along the edge is not always optimally guaranteed.

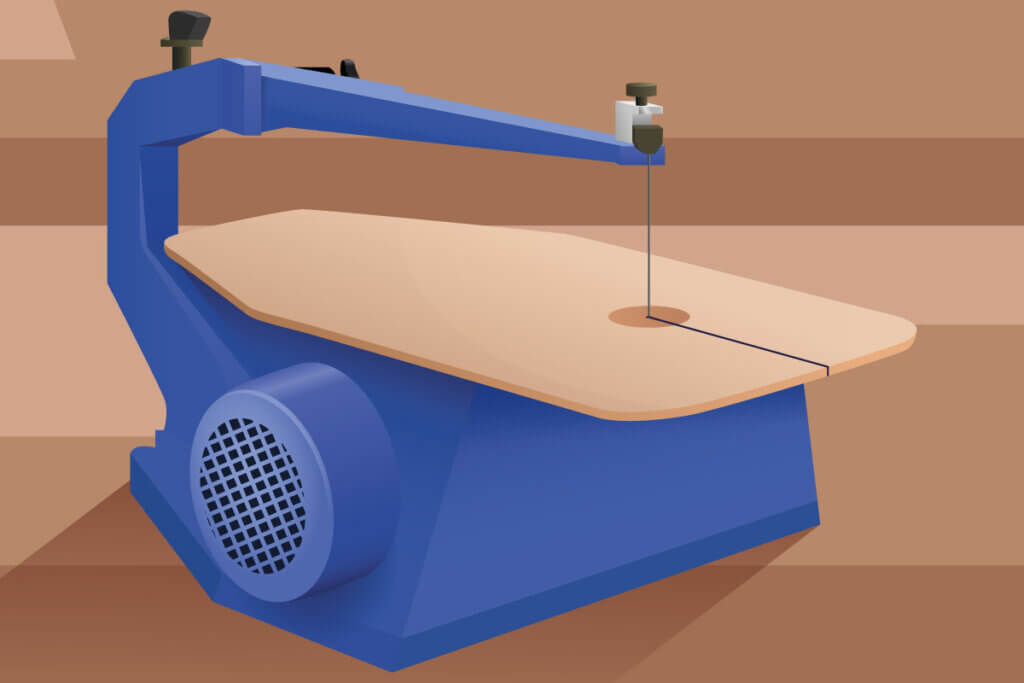

A scroll saw consists of the following components:

- Work table

- Adjustable table inclination

- Saw blades or saw wires

- Clamping device (with tool or without tool)

- Adjustable motor

- Pendulum hoist

- Extraction system or blower

Work table and tilting device

As a table-top unit, the scroll saw is a semi-stationary machine. This means that although it can be carried anywhere, it is ultimately parked in a suitable place. When working with the scroll saw, operators have both hands free so that they can concentrate fully on guiding the workpiece.

There is a tilting device under the top of the worktable. Depending on the type of machine, this may or may not have a locking function. In any case, there is a scale there. Even if there is a locking function, for example every five degrees, the inclination of the worktop can also be adjusted in intermediate steps and locked. This allows any cutting angle to be incorporated along the thickness of the workpiece.

Saw blades and clamping device

The saw blades or saw wires are the cutting and consumable materials of a scroll saw. They can be changed in a few easy steps. Saw blades have a width of a few millimetres. This makes them particularly useful for straight cuts or flat curves. With tight curves, however, saw blades often produce undesirable radii along their width. Thin saw wires are better suited for this. Due to their round cross-section, they can work equally well in any direction.

Inexpensive scroll saws are usually equipped with clamping devices for the saw blades or saw wires, respectively, for which a tool – usually a small screwdriver or a narrow hexagon socket spanner – is required. On high-quality models, the cutting medium can be changed without a tool. This makes the blade change much more efficient. A quick-change device is advantageous for processing large numbers of pieces, as it reduces changeover breaks to a minimum.

Motor and blower

The motor is equipped with an adjustable potentiometer even on inexpensive scroll saws. This allows the speed to be adjusted. The rotary motion of the motor is transmitted via a gearbox to a pendulum lifting mechanism. This converts the rotation into an up and down movement. The clamping device for the sawing material is attached to the pendulum lifting mechanism. The faster the motor rotates, the faster the pendulum lifting mechanism moves. Fast movements on the reciprocating mechanism allow for fast operation, but also generate a lot of heat. This can cause the saw blade to crack or cause charring on the workpiece.

Tip for avoiding charring

To avoid charring the workpiece, stick a piece of parcel tape along the cutting line. This absorbs so much heat from the cutting wire that the wood underneath is no longer charred in the cut.

Finally, a blower or an extractor ensures that the cutting point always remains clean.

What to look for when buying a scroll saw

The scroll saw is a rather special tool for a rather narrow working area. The market for these tools is divided into two segments: low-budget products and models from the upper price segment.

Scroll saws from the low-budget segment

The high level of design safety of scroll saws makes it possible to select even low-budget devices without hesitation. Since scroll saws are technically relatively uncomplicated, it is also possible to use a model from the lower price segment for occasional use in the craft room without any problems. On the other hand, users of budget models have to make concessions in terms of performance, workmanship and comfort. Above all, the workmanship of the mechanics, especially the locking of the work table, often leaves much to be desired. In addition, inexpensive machines are often not sufficiently damped against the vibrating action of the pendulum movement. This means that locks or even housing screws can quickly come loose and the machine practically disassembles itself during work. When buying a cheap scroll saw, consumers should therefore regularly invest time in retightening and checking all clamping and holding elements.

Inexpensive no-name products or machines of well-known budget brands require a lot of manual setting, adjusting and checking. Working can therefore become somewhat unpleasant in the long run if an ear constantly has to be turned off to identify suspicious noises and the adjustment of the machine has to be checked after every cut. In addition, important components, for example adjustment and clamping screws, are often made of thin plastic on cheap machines. If a clamping screw is tightened with too much force, it can break suddenly. There is another problem: spare parts are usually not available for machines from discounters.

Scroll saws from the upper price segment

On the other side of the spectrum, there are some manufacturers who have concentrated entirely on high-quality special saws. Their products are designed to satisfy very demanding cabinetmakers. The quality of these machines is beyond reproach. Above all, dimensional accuracy and safe adjustment are always guaranteed. Users can concentrate fully on their work, even on larger and more complex projects, and do not have to worry about whether the machine will keep its settings. If something does break, the manufacturers of commercial scroll saws always have an assured supply of spare parts. Some of the manufacturers actually produce only one type of scroll saw.

The high-end products have their price: they easily cost five times what a scroll saw from a budget manufacturer costs. However, if a demanding project with lots of filigree work and high-quality materials is on the agenda, consumers should still consider buying a top-of-the-line scroll saw.

The golden mean?

There is practically no range of scroll saws in the mid-price range. The well-known quality brands for electric machine tools do not have these devices in their product range. Instead, they carry a selection of band saws that can also be operated with fine saw wires. These fine band saws can be used for the same work as the scroll saws, but offer some advantages. These include, for example, a quieter, lower-vibration operation.

Precautions when using a scroll saw

A scroll saw is nowhere near as dangerous as a circular saw, angle grinder or band saw. Even in the worst case, where operators touch the cutting wire, the most that can happen is a cut. In addition, little force is required to cut thin material. Pushing through thick boards and beams, as is common on construction circular saws, for example, does not take place on a scroll saw.

Nevertheless, there is a certain risk of injury or other health risks. However, by taking a few safety precautions, users are well protected against health hazards.

Wear a respirator and safety goggles

Working with a scroll saw produces a particularly fine dust. Depending on the material being processed, respirable particles may be produced. Therefore, we recommend using a suitable fine dust mask whenever working with a scroll saw or other metal-cutting equipment.

In addition, when sawing, micro-fine splinters often fly around, which can get stuck in the eye and cause a bad inflammation. It is therefore advisable not to do without suitable eye protection even for this seemingly uncritical work.

Use high-quality cutting materials

Cheap or low-quality cutting wires and saw blades are not only a nuisance when they produce unclean cutting patterns. They usually only last a few minutes. Constantly changing the saw wires is time-consuming and, on top of that, dangerous, because with every crack, users can slip with the workpiece and injure themselves. Even if an inexpensive model was chosen when purchasing the scroll saw, only first-class quality cutting tools should be used.

Check the machine before each use

Before switching on the machine for the first time at the work site, check the following points:

- Condition of the housing

- Condition of the cables

- Condition of the switches

- Stability of the machine

- Contact with water

If damage is visible or the tool otherwise looks suspicious (for example, if it develops the smell of burnt plastic), users should stop using it and have it professionally repaired. Local fire brigades and electrical shops can provide further information on how to recognise defects in electrical tools and how users should ideally react to them.

Care and maintenance

Because scroll saws are metal-cutting machines, they produce a particularly fine dust that can get trapped throughout the mechanics. Therefore, regular cleaning and checking of a scroll saw is an inevitable part of the job – no matter how expensive the machine was originally. The usual care and maintenance steps for scroll saws are as follows:

- Visual inspection: especially with inexpensive machines, it is advisable to check them thoroughly before each use. Before using the machine, make sure that all housing screws are tight and check that there is no play in any joints and that there is no damage. The two minutes you invest in tightening all housing and joint screws will pay off in much more relaxed working.

- Compressed air cleaning: Part of the dust produced gets into the inside of the machine. As a technical layman, however, you should never take the machine apart to clean it from the inside. It is sufficient to blow it out along the ventilation openings with compressed air. Two to three bar is sufficient here. This will prevent the sharp jet of air from causing damage to the inside of the machine.

- Exterior care: Clean the outside of the machine with a damp cloth. A light soapy water solution is sufficient as a cleaning agent. After wiping, rub or blow dry the machine.

- Maintenance: All further maintenance steps, such as lubricating joints, may only be carried out in accordance with the operating instructions for the machine. Careless use of lubricants and solvents can damage the machine.

Image 1: © Kadmy / stock.adobe.com | Image 2: © FinalCheck | Image 3: © Erik / stock.adobe.com | Image 4: © Milissenta / stock.adobe.com

36 reviews

36 reviews