Electric planer purchasing advice: how to choose the right product

- What you need to know

- Planes are used to cut indentations in wood.

- Electric planes are equipped with a rotating cutterhead that lifts chips from the surface of the wood.

- An electric planer is used to cut shallow channels, called rabbets, in a workpiece.

- The tools are ideal for removing old varnish or paint.

Chip(n)end processing of wood

A planer is a tool used to lift chips from a material. As a rule, this is wood. While the classic hand plane has a fixed cutting edge, the electric plane has a rotating cutter with inserted cutting edges. When the electric planer is passed over a workpiece, it cuts an even, shallow channel into it. This ability can be used for various purposes in the craft.

Ablation

An electric planer can be used to level uneven surfaces and bring workpieces to the appropriate size. It is used, for example, for warped door frames: The layer of wood that makes closing difficult is planed off and the problem is solved. If the board is a little too long, the electric plane can also help. It is also a great support in the treatment of unsightly surfaces. Old paint or varnish is quickly removed with the electric tool.

Folding

A rebate is a step or edge in a workpiece. Rebating is often used to join different parts together, such as doors, windows and furniture. Thanks to the rebate on the door frame, the door can be closed seamlessly.

Chamfering

A chamfer is a beveled surface on a workpiece edge. Creating a chamfer is called “chamfering”. This technique can be used, for example, to defuse hard edges on furniture. However, a chamfer can also serve purely decorative purposes.

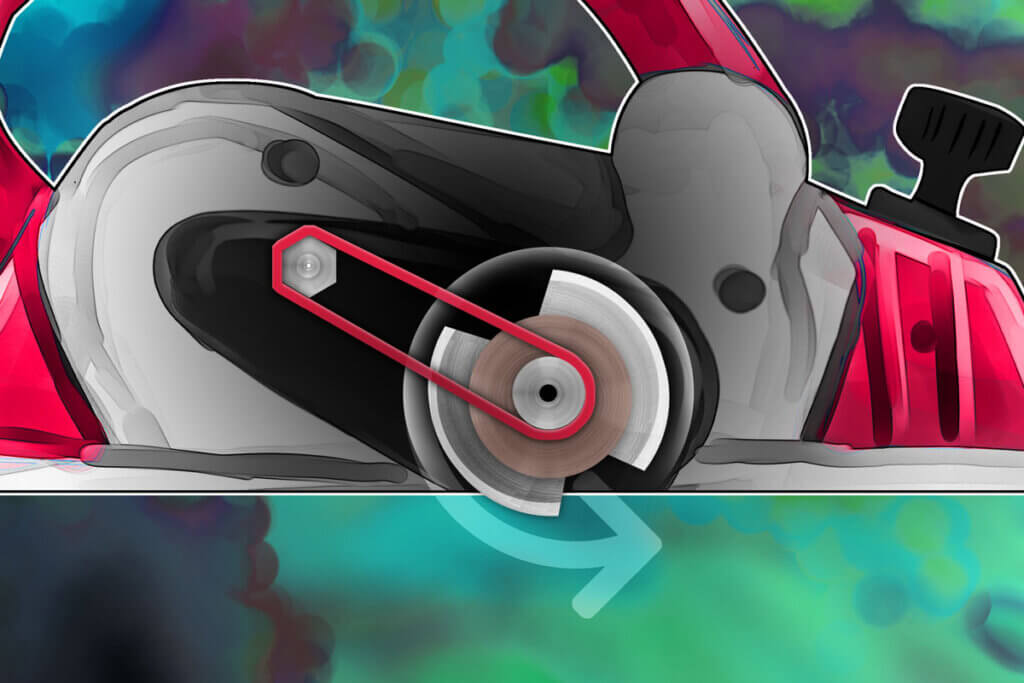

Functionality and terminology

The conventional hand plane has a sharp blade on its underside – similar to a razor – which removes the top layer of wood. The functional area of an electric planer is comparable, however, significantly less own power must be used for woodworking. Electric planers usually have two blades connected to a so-called planing shaft. This planer shaft rotates at several thousand revolutions per minute, easily lifting wood chips. Depending on how the depth of cut of the plane is set, very precise results can be achieved with this practical tool.

Those who have not yet dealt extensively with electric planes should familiarize themselves with the following terms:

Plane sole:This is what the bottom plate of the plane is called. The sole of the plane consists of two halves, which are separated by the knife. The chip depth can be adjusted by adjusting the front half.

Planing width:The width of the planing blade is also the width of the surface that is planed when the tool is used.

Chipdepth:The chip depth or chip thickness determines how much material is removed with one thrust. With most electric planes, the chip thickness can be adjusted between zero and three millimeters.

V-groove: This is a groove in the sole of the electric plane. The V-groove enables beveling of edges on workpieces. Some devices are equipped with multiple V-grooves.

This is what you should look for when buying an electric plane

With an electric planer, the most important thing is technical data. Pay attention to how many turns the device can do per minute. The width and depth will tell you if it is suitable for your project.

Corded or battery powered?

Like many other power tools, electric planes are available in two types: corded, which require power from a wall outlet, and battery-powered models, which are suitable for mobile use.

Corded electric planes basically achieve higher performance than battery-powered variants. Only a conventional 230-volt household socket is required for operation. Since there is no battery installed, corded electric planes are both lightweight and handy. They are also cheaper than models with battery. Disadvantage of electric planer with cable is that it allows only a certain range of motion. In most workshops, however, this problem is negligible because there are enough sockets.

If you need an electric planer for mobile use beyond the workshop, you should choose a model with a rechargeable battery. One offers more freedom of movement due to the lack of a cable, but it is heavier and less powerful.

Speed and power

In order for the work with the electric planer to be clean and fast, a certain power is required. Interested parties should be guided by the wattage and speed. The power in watts describes the strength of the electric motor that drives the planer shaft. It is particularly relevant when deep cuts are to be planed. A powerful planer is also required for hard woods such as oak. A powerful machine should have at least 600 watts. Electric planes with 800 to 900 watts of power usually achieve good results and often have a higher speed. However, it often remains difficult to tell the true power level of an electric planer from its wattage rating.

More meaningful than the power in watts is the speed. It describes how often the planer rotates per minute. Most electric planes manage between 13,000 and 17,000 revolutions per minute. Even many inexpensive models reach 14,000 revolutions per minute. The best electric planes even reach 19,000 revolutions and more. A high speed is especially advantageous when planing flat folds. When buying, look for speed regulation, as not all devices have it.

Blades of the knife roller

Even a powerful machine with high speed will not achieve the desired result with poor knives. Dull knives are more likely to tear the wood than plane it. In the trade there are three common varieties of knives:

Planing knives made of HS steel (short for: High Speed Steel) can be resharpened. Those who have the necessary grinding tools are therefore at an advantage. HSS knives are ideal for working with soft wood. However, HSS knives are increasingly being displaced by tungsten carbide knives.

The resistant tungsten carbide also copes with hardwood. Nowadays, electric planes are mainly equipped with blades made of this material. Since tungsten carbide is very hard, it is difficult to regrind.

Many manufacturers now rely on reversible knives, which should not be ground. They have two blades and can be easily reversed when worn.

Regrinding the knives not always advisable

Modern planer knives are often not designed to be resharpened. An improperly sharpened blade can create an imbalance during work that puts a lot of stress on arms and shoulders. Incorrectly sharpened knives also create grooves on the planed surface and thus impair the appearance.

Width and depth

How versatile an electric planer can be used depends largely on its design. Interested parties must pay attention to three parameters when buying: the depth of cut, planing width and depth of fold.

The chip depth tells how thick the chips are that the electric tool removes. Most electric planes can be set to a depth of cut between zero and three millimeters. Some designs even manage four millimeters. For most projects, two millimeters of chip depth is sufficient.

How deep you can cut into a workpiece with the electric planer is revealed by the rebate depth. With most devices, a fold depth of up to 10 millimeters can be set, and some even manage 15 millimeters. The fact that cutting cannot continue beyond a certain fold depth is due to the housing of the tool, since at some point it rests on the edges of the fold. Depending on the project, the fold depth is therefore crucial for successful implementation.

How wide the rebate becomes is in turn related to the width of the planing knife. A standard electric planer has a planing width between 80 and 85 millimeters. It should be noted that the device itself measures more in width. Therefore, to work on hard-to-reach places, it is sometimes necessary to switch to the hand plane.

Other features

V-groove are V-shapedindentations on the underside of the plane sole. They make it possible to plane off corners and edges. Thanks to the V-groove, the electrohoble can be guided along the entire length of the edge. The result is a beveled edge that makes a better visual impression while reducing the risk of injury.

An electric planer vibrates during operation and must therefore be safe to grip and guide. Most models have ergonomically shaped and rubberized handles. A second handle provides improved guidance. Often this is the chip depth adjustment knob at the same time. To prevent the chip depth from being accidentally changed during use, it must be possible to lock it firmly in place.

Precise work with the electric planer is almost impossible without a guide rail. The guide rail ensures that the plane is guided parallel to the edge of the workpiece and provides a handsome result.

When working with an electric planer, fine dust is generated. If this is inhaled, it can cause damage to health. With many models, the chips are simply ejected to the side. Good electric planes are equipped with their own suction system. Such devices have a connection socket to which a special dust bag or else an industrial vacuum cleaner is connected.

The so-called parking shoe is located on the sole of the device. This is not a shoe in the true sense, but a device that raises the sole of the plane slightly when it is set down, so that it does not touch the ground. In this way, the knives are preserved and protected.

Replacing the planing knives

For a clean planing result, you need sharp knives. When noticeable nicks or deformation are visible on the blades or it feels dull, it’s time for a change. In the DIY sector, it is necessary to replace the blades about every half year.

To insert new blades, first remove the cover on the bottom of the electric plane. Now you have a clear view of the roller. The knives are inserted crosswise into the matching clamping profiles of the roller. The fastening screws of the roller must often be loosened with an open-end wrench. Refer to the operating instructions of your device for information on how to remove the roller.

In some circumstances, the knives are fixed with fastening screws that you have to unscrew. On many models, however, the blades can simply be pushed out of the clamping profiles at the side. Make sure to push the new blades into the profiles the right way around. However, it is often not even possible to use the knives the wrong way round, as the profile shapes only allow the appropriate direction.

Safety instructions

An electric planer is a powerful tool with high speed. Use is therefore always associated with hazards against which appropriate safety precautions must be taken. Wear your clothing so that it cannot get caught in the device. For example, it is advisable to tuck shirts into pants.

Make sure that there are no hard objects on or in the workpiece that could damage the blades. These include nails and screws as well as smaller objects such as staples. Brush the workpiece with a wire brush beforehand, as planing knives are very sensitive. Before using the electric planer, the workpiece must always be firmly fixed.

Cutting at high rotational speed produces not only chips, but also very fine wood dust. An electric planer with an extraction system is therefore highly recommended. In principle, it is advisable to wear a nose mask when working with the plane.

If the blades are blunt or the electric planer is used incorrectly, wood splinters can be ejected from the device. So when working should not do without safety glasses. Due to the loudness, hearing protection is also advisable. Many units reach 80 to 90 decibels, which is the noise level of a major road.

Electric plane or hand plane?

Compared to the hand plane, the electric plane may at first appear to be the more practical tool – yet the hand plane is still used daily in many workshops. This is because it is still the better choice for certain applications. The type of plane you need depends on the work you want to do with it.

A hand plane is particularly suitable for smaller jobs that require high precision. Since the motorless hand plane does not vibrate, it is very easy to control by hand. Due to its small size, it can also be used in hard-to-reach places. Properly handle a hand plane requires some practice. It is therefore more for advanced DIYers who want to do fine carpentry work. Those who do woodwork primarily as a hobby and are looking for relaxation will also be happy to do without a loud electric planer and instead reach for the classic tool.

The electric planer is easier to use, as no special planing technique is required. However, it works coarser than a hand plane and is recommended mainly for doing larger jobs. With an electric plane, the cabinet wall is freed from the old varnish in no time. In principle, such a tool is well suited for use on a construction site. For fine work it is better to use a hand plane. Also, because of the way it works, patterns can be left on the surface of the wood, which some people are bothered by.

Image 1: © FinalCheck | Image 2: © iammotos / stock.adobe.com | Image 3: © Andris Daugovich / stock.adobe.com | Image 4: © Pixel-Shot / stock.adobe.com

no reviews

no reviews