Rotary hammer purchasing advice: how to choose the right product

- What you need to know

- A rotary hammer is a tool that can be used to work on very hard rock or concrete. The main functions are drilling holes and chiseling.

- Electric rotary hammers are best suited for home and handymen. Their power is sufficient for most work in these areas.

- You can tell how powerful a rotary hammer is by its impact energy in joules, the number of blows, and the motor power in watts.

- Rotary hammers typically use a special shank system for attachments called SDS.

- With an interchangeable drill chuck or a drill chuck adapter, you can also use ordinary drill bits.

When push comes to shove

For hard materials, a simple drill or hammer drill is often not enough. They also sometimes reach their limits with thick house walls in old or new flats: drilling a hole in the wall to fix a shelf, for example, becomes a test of patience. With a rotary hammer, you can easily master this task. It specializes in working hard rock and concrete. The largest and most powerful models are therefore found in mining applications, among others, but DYIers will also find the right tool in the wide range.

A rotary hammer combines the back-and-forth action of a hammer drill with the rotation of a drill. The applications of rotary hammers and hammer drills are therefore similar: both machines drill holes in harder materials. That is why beginners often ask themselves how the two tools differ from each other and which tool they need for the job at hand.

The difference between a rotary hammer and a hammer drill

The biggest difference between a rotary hammer and a hammer drill is the hammering mechanism. A hammer drill has two toothed gears that produce a hammering in the axial direction while rotating. The speed of rotation determines the number of blows: the higher the speed, the more effective the hammer drill. However, the machine doesn’t have its own drive that generates the blow; the impact energy therefore depends on the force the craftsperson exerts on the tool to drill. The hammering can be turned off with a switch, which allows drilling in materials such as wood, metal, and plastic.

The hammering mechanism of a rotary hammer, on the other hand, consists of a moving mass that strikes the drill bit with the help of an electric, pneumatic, or hydraulic drive. The craftsperson doesn’t have to apply any additional force: the higher the drive force, the more effective the rotary hammer. The rotation speed and number of blows of a rotary hammer are lower than those of a hammer drill, but the energy of each individual blow is higher. With the rotary function switched off, the rotary hammer can also be used for chiselling.

If you mainly want to drill through hard rock and concrete, go for the rotary hammer. If you don’t need such high impact energy and also want to work on softer materials such as wood, then the hammer drill is more suitable.

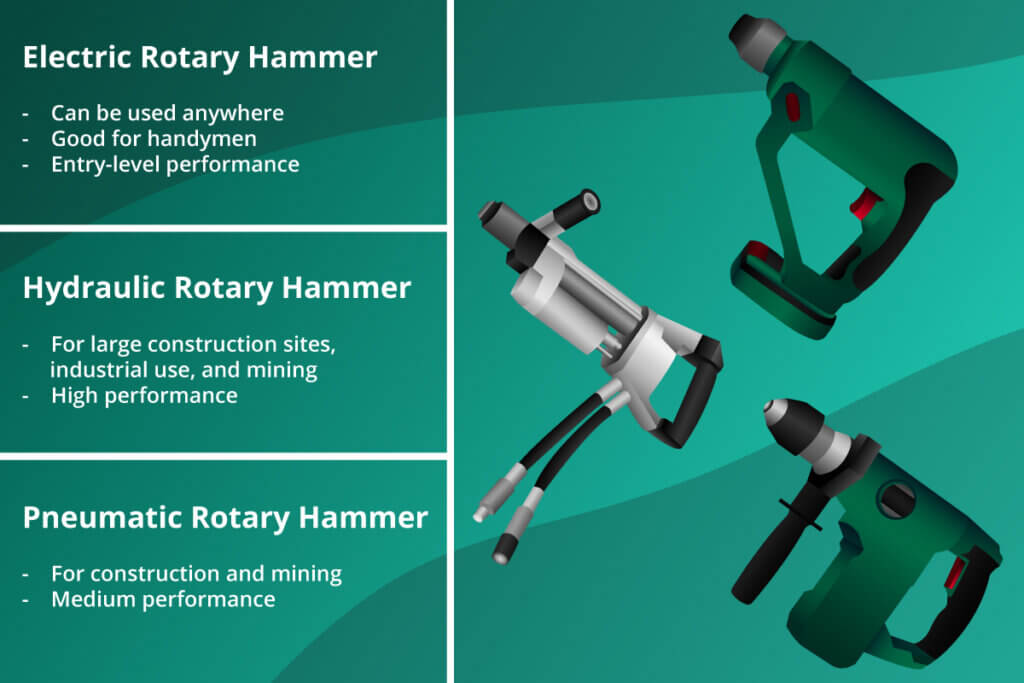

Types of rotary hammer and how they work

A rotary hammer consists of a movable drill bit that rotates in the axial direction, a drill chuck in which the drill bit is clamped, and the impact mechanism with drive that generates the impact energy. The drill chuck is the component to which you attach the desired drill attachment; however, in order to perform the simultaneous rotating and percussive movement without loss of power, there is a small clearance between the drill and the chuck so that only the attachment rotates. The rotary hammer types differ on the basis of the drive: electric, pneumatic and hydraulic.

Electric rotary hammers can be used almost anywhere and are ideal for DIY and craftspeople. While their power is the lowest of all, it is perfectly sufficient for most projects in these areas. In the absence of power sockets, power generators or rechargeable batteries ensure easy usage.

Pneumatic rotary hammers are more suitable for construction sites and mining than for home use. They work on the basis of compressed air, which is regulated with a valve. Pneumatic tools are a lot more powerful than their electric counterparts. To use them, however, you need a compressor that generates the necessary compressed air.

There are also hybrids: electric rotary hammers with pneumatic hammering. These models combine the high impact energy of pneumatic models with the flexibility of electric devices. In contrast to purely pneumatic rotary hammers, they are therefore also suitable for do-it-yourselfers.

The most powerful devices are hydraulic rotary hammers, which drive the piston with hydraulic fluids. They are optimized for use on large machines, for example as demolition hammers on excavators. Hydraulic hammers are very suitable for large construction sites, industrial plants or mining, but they are not relevant for professional craftspeople or DYIers.

Typical attachments for rotary hammers

Depending on the field of application, different attachments are available. For fine chisel work, for example, a wide chisel is unsuitable.

The pointed chisel has a pointy tip that is either tapered towards the shank or has four to six flanks. It is excellent for more intricate detail or when you want to strike deeply and quickly into the material.

A channeling chisel has the shape of a hollow semicircle in cross-section, open at the top. It is suitable for creating joints in masonry, for example for cable ducts.

Flat chisels are universal chisels: depending on how wide the tip is, different tasks can be performed by such chisels. The most common use of a flat chisel, however, is to knock off old tiles.

The last important chisel is the spade chisel with a wide tip for splitting different materials. Due to its high splitting power, it is suitable even for the hardest materials.

The classic attachment is the concrete drill bit. It is available in several lengths and diameters and with two or four flanks.

A core drill bit drills large holes in concrete and stone. Unlike other drill bits, which pulverize the removed material in the drill hole, a cylindrical drill core is produced when working with a drill bit.

So-called multi-purpose drill bits allow you to drill through even reinforced concrete. Although this is done more slowly than with tools that are optimized for, say, steel or concrete, their strength lies in their multifunctionality.

What you should look for

When you look at the product description of an (electric) rotary hammer, you are confronted with technical terms and measurements that you may not be able to classify, for example the impact energy in joules. Finding the right tool with the features you really need among the large number of rotary hammers can be a challenge. The following criteria will help you make the right purchase decision.

The output

The drive generates the power that the rotary hammer needs to implement the characteristic rotary and hammer motion. The power of the drive in watts is therefore an important criterion for determining the efficiency of the entire device. You will often find this information in product descriptions under the term ‘rated input power’. The higher the wattage, the higher the impact energy. An electric rotary hammer for private use should have at least 700W; this is enough for most projects at home.

The hammering

Two factors play an important role in the hammering: the impact energy in joules and the number of blows per minute. Together they determine the efficiency of the rotary hammer.

The higher the impact energy, the better the hammer works on hard stone. However, high impact energy also means a high weight and fewer blows per minute (bpm). To determine the number of blows, manufacturers measure how often the drill hammers within one minute when idling. You can find this impact rate under ‘rated speed’ in the product description.

For hard concrete, a medium number of blows and a medium impact energy are recommended; for softer materials, the impact energy should be smaller and the impact rate higher. In contrast, high impact energy with few blows is better for hard or rough work such as demolition and very hard concrete. Depending on the materials and the place of use, you should therefore weigh up the relationship between impact energy and impact rate.

For private use, an energy of about two to four joules per blow and an impact rate at rated speed of 4000 to 5000 rpm are recommended.

The rated speed

Another information you will often find in product descriptions is the rated speed. It indicates how often the drill chuck rotates in one minute without drilling attachments. While a high speed is recommended in most cases, a very high speed with low impact energy means that the rotary hammer cannot drill through softer concrete. With some models, the number can be adjusted in steps or continuously and thus adapted to the material requirements.

The weight

Depending on the type of drive, rotary hammers can be very heavy; even the compact electric rotary hammers for domestic use weigh between 4.5 to 13.5 pounds (2 to 6kg) on average. Heavier models tend to be more powerful, but bear in mind that you will need to hold the tool in your hands throughout use. A powerful rotary hammer is of no use if you cannot operate it because of its weight. A lighter model is more advantageous, especially for long-duration work. It is therefore advisable to have this in mind and, if in doubt, choose a lighter rotary hammer with less power.

Handling and comfort

If you want to use the rotary hammer as a chisel, you should be able to easily switch off the rotary function. Some models also have an impact stop, which makes them combination tools: a switched-off impact mechanism allows you to drill into softer materials such as wood, as the material doesn’t burst.

A clockwise and anti-clockwise rotation come in handy when the drill head gets stuck in concrete. In this case, you can have the drill bit rotate in the other direction, which makes it easier to free it.

For the necessary comfort, the rotary hammer should not only have an appropriate weight but also sit comfortably in the hand. Soft rubber handles contribute to this. Models with high impact energy and rotational speed often vibrate during operation. To protect the arms from these vibrations, some powerful models have vibration damping in the handle.

Important accessories

In addition to various drill attachments, there are other accessories that are useful for working with rotary hammers: protective equipment for your safety as well as equipment for the rotary hammer itself.

For your safety

Perhaps the most important protective device you need when working with a rotary hammer is hearing protection. Most rotary hammers reach volumes of more than 90 dB, and very powerful devices even exceed 100 dB. Prolonged use without protection could permanently damage your ears, as this is already possible at a volume of more than 85 dB.

When you drill or chisel with a rotary hammer, debris, dirt, and dust are produced. With safety goggles, you can prevent such particles from getting into your eyes and causing injuries. This can happen quickly, especially when drilling overhead.

Gloves are not absolutely necessary, but they provide a firmer grip and also protect you from injury, for example if you come into contact with the still-hot drill shortly after working.

For the rotary hammer

Modern rotary hammers are equipped with a special quick-action drill chuck so that you can change the different drill attachments quickly and without a drill chuck key. The tool-free change is based on special flanks in the heads of the insert tools, which not only enable quick fixing but also ensure better power transmission between the machine and the attachment. Conventional drill bits are not compatible with these quick-change systems due to their round and smooth shanks:

- SDS-plus with a shank diameter of 10mm.

- SDS-max with a shank diameter of 18mm.

- SDS-quick with a shaft diameter of 6.8mm.

What does ‘SDS’ mean?Today’s SDS quick-action system, or more precisely SDS-plus, is a Bosch development based on Hilti’s insertion system. Originally, ‘SDS’ stood for ‘Stecken – Drehen – Sichern’, German for ‘Insert – Twist – Secure’, but for international markets, Bosch calls it now ‘Special Direct System’. After Bosch’s patent expired, SDS-plus became the standard for rotary hammers independent of manufacturers.

To attach drill bits with a straight shank to a rotary hammer, you need an interchangeable drill chuck, which you put onto the drill shaft by means of a lock and coupling. The larger selection of drill attachments also allows you to use the hammer for materials such as wood or metal. In this way, you combine several tools into one.

Another practical feature is a depth stop, which ensures that you do not exceed the preset drilling depth. With a depth stop, your holes have exactly the depth you need.

Chisel paste is important for the maintenance and care of your rotary hammer, as the area between the shaft and the chuck should always be well greased. If your machine is equipped with an interchangeable chuck, you should also apply the chisel paste to the coupling to the pick-up shaft.

The right care

In order to enjoy your rotary hammer for a long time, you should clean and maintain it regularly. As the drill bit moves axially back and forth in the SDS chuck, friction occurs between the shaft and the chuck. If this area is not sufficiently greased, wear and tear will occur, which is why it should be checked before use. The coupling on a tool with an interchangeable chuck also wears out, making the drill less accurate. For drilling in metal, however, a certain accuracy is essential, which is why this area must also always be sufficiently greased.

You should not neglect regular maintenance of the motor and its ventilation. Drilling in concrete causes a lot of dust; electric tools, including rotary hammers, are sensitive to this. Therefore, it is advisable to clean the outside of the device with compressed air. Furthermore, it makes sense to clean the inside of the casing. However, you should leave such cleaning to a specialist, as opening the housing on your own will result in the loss of warranty claims.

Image 1: © FinalCheck | Image 2: © Dan Race / stock.adobe.com | Images 3-4: © FinalCheck | Image 5: © Anselm / stock.adobe.com | Image 6: © Nik / stock.adobe.com

no reviews

no reviews