Stove fan purchasing advice: how to choose the right product

- What you need to know

- Stove fans distribute the upward rising warm air from a stove throughout the room.

- They work without an external power supply, as the power is generated by the temperature difference between the stand and the cooling fins of the fan.

- They are suitable for all ovens without a thermally insulated surface.

- Stove fans start working at stove temperatures between 122 and 176°F (50 and 80°C) depending on the model.

- A bimetallic strip on the underside of the stand serves as overheating protection.

Support for the furnace

Imagine a cold, wet winter day, where you can sit inside next to the warmth and dancing flames of a stove filled with wood. Sounds great, doesn’t it? In terms of creating a cosy atmosphere, stoves are miles ahead of conventional heaters. However, it sometimes takes a long time for the room to warm up completely. This is due to the way stoves work: In the case of fireplaces, the air around the stove heats up and expands. Instead of being immediately distributed in the room, the warm air first rises to the ceiling. As a result, the air near the ground initially remains cool. The larger the room, the more time it takes for the warm air to disperse. The solution to reach the desired room temperature faster is a stove fan.

Stove fans, also called log burner fans, distribute the rising warm air evenly in the room. They are usually placed on top of the stove, so they blow the air directly from the stove’s body into the room. As a result, warmth quickly distributes throughout even large rooms.

Stove fans are cost and energy efficient: Less energy and heating material is needed to heat a room, which in turn reduces costs and emission. With a wood-burning stove, for example, you will need less wood for the same heat output. In addition, common stove fans are easy to operate and rarely malfunction.

However, stove fans are only suitable for stoves whose surface also heats up during operation, as a specific minimum ambient temperature is required for use, depending on the model. While stove fans are usually suitable for wood and pellet stoves, they are not suitable for those with a natural stone surface. Tiled stoves, open fireplaces, storage heaters, and radiators are also not suitable for the use of stove fans, as their surface does not heat up sufficiently. Another disadvantage is the noise emission, which is pretty low at a maximum of 25 dB, but should still be mentioned.

Advantages

- Fast and even heat distribution

- Also suitable for large rooms

- Not prone to malfunction

- Energy efficient

- Cost-effective

- Simple operation

- Low maintenance

Disadvantages

- Not suitable for all stoves

- Noise emission

How stove fans work

Unlike other fans, stove fans usually operate without an external power supply or integrated battery. Many classic models use a so-called Stirling hot air fan. This makes use of the thermal expansion of the air to generate mechanical energy, which in turn drives the rotor blades. The faster the blades rotate, the stronger the airflow and the faster the heat is distributed in the room. However, models with a Stirling hot air fan are susceptible to dirt and dust.

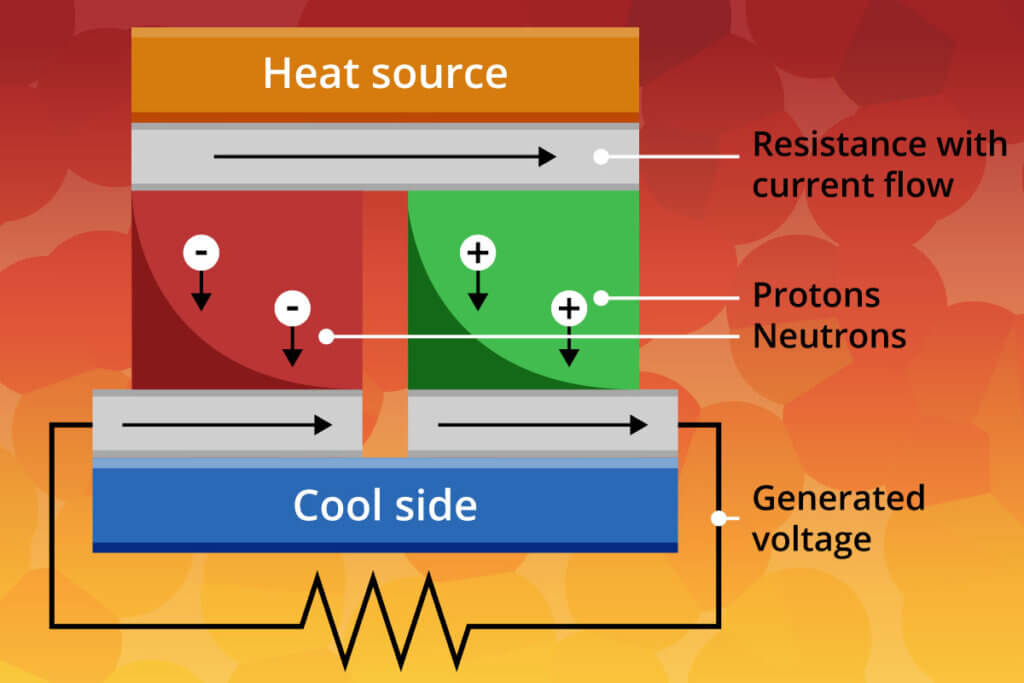

Modern stove fans are usually thermoelectric devices that generate energy through the temperature difference between the upper and lower parts of the fan. Thermoelectric stove fans are equipped with a motor that drives the rotor blades. It receives the necessary current from the integrated Peltier element, which converts the heat of the stove’s surface into electrical potential.

On the top of the fan, there are cooling fins that cool the air. Thus, the stove fan ensures a constant temperature difference. Once the stove reaches a certain temperature, the Peltier element automatically generates energy and the motor drives the rotor blades. If the surface temperature of the stove drops, the fan also slows down until it eventually stops. Stove fans are therefore self-regulating and don’t require any active handling or adjusting during operation.

Peltier element, but Seebeck effect?

Anyone studying the operation of stove fans will inevitably come across the Peltier and Seebeck effects. These two each describe a different effect in the field of thermoelectricity. The confusing thing about stove fans is that while they use the Seebeck effect, the essential component for this is known as the Peltier element. This gives the impression that the Peltier effect is in action. This is not the case: The Peltier effect basically describes the opposite of the Seebeck effect.

The Seebeck effect states that two different metal rods in a circuit produce voltage when their junctions have a temperature difference. It is precisely this effect that stove fans take advantage of. In the Peltier effect, on the other hand, an electric current flow causes the temperature to change. It is used mainly in refrigeration devices.

What to look out for when buying

Stove fans are simple devices: You cannot turn them on or off, and there are no special functions and settings. It is important that they start working at the lowest possible temperature and distribute warm air quickly enough throughout the room.

Temperature

Stove fans can only start working at a certain temperature. That is why it is so important that the surface of the stove gives off enough heat. The minimum temperature is between 122 and 176°F (50 and 80°C), depending on the model. The optimal temperature is even higher because the rotor blades rotate faster as the heat increases and can thus perfectly distribute the air in the room. On average, this temperature is 302°F (150°C). The maximum temperature that stove fans can tolerate is usually 662°F (350°C).

Material

The material of stove fans must withstand high temperatures. If they were made of plastic like conventional fans, the housing would melt in a very short time. Therefore, anodized aluminum is mainly used.

Aluminum is characterized by high thermal conductivity and low weight. Anodizing gives the material an oxide layer that effectively protects it from corrosion and rust. In addition, the oxide layer ensures that the aluminum can withstand temperatures between 662 and 752°F (350 and 400°C). The temperature resistance of the material must be slightly higher than the maximum recommended working temperature, i.e. 662°F (350°C).

Construction and properties

To prevent the chimney fan from exceeding the recommended working temperature, there is a small bimetallic strip on the bottom of the fan’s stand. This serves as overheating protection. If the temperature of the fan threatens to exceed 662°F (350°C), the bimetallic strip bends downward. Thus, it breaks the direct contact between the fan and the surface of the stove.

A large, smooth base is ideal: The larger the foot, the more surface area is available to absorb the heat from the stove. It is important that the stove also has a smooth surface.

The cooling element or cooling fins are there to create the highest possible temperature difference between the upper and lower halves of the stove fan. For this purpose, it is useful that the cooling element is also large. Furthermore, an insulating layer should separate the cooling element from the rest of the components to ensure its low temperature.

Since the stove fan needs some time to cool down after use, a foldable carrying handle is convenient. This allows you to lift the unit from the oven and store it without getting burned. Furthermore, an integrated thermometer is helpful to keep a close eye on the oven temperature.

Rotor blades

Stove fans usually distribute warm air with the help of two to five rotor blades or vanes. There are also models with two motors, each driving three blades. The more blades there are, the greater the amount of air the fan can distribute, even with only a few revolutions. The size of the rotor blades also influences the air circulation. Large rotor blades have more surface area with which they can spread the air in the room. Therefore, they are particularly suitable for large-area rooms.

A common recommendation is to match the length of the rotor blades with the square footage of the room. To heat small rooms up to 161 square feet (15m²), rotor blades with a length of 6 inches (15cm) can be used. While it is certainly possible to use longer designs than necessary, keep in mind that large and heavy rotor blades require more heat to get moving — and more heat means higher heating costs.

Air circulation

Many stove fans also provide a value for air circulation or airflow. It describes how quickly the fan can distribute the warm air throughout the room. The higher the value, the faster the room is heated up. Manufacturers usually use the unit cubic feet per minute (cfm), or in some cases cubic meters per hour.

For example, Voda‘s dual-motor stove fan allows airflow between 590 and 645 square meter per hour. One cubic meter per hour is equal to 0.5885778662613 cfm. So to convert the value to cubic feet per minute, multiply it by 0.589 rounded up. This results in 347.51 cfm. Other single-motor furnace fans have an airflow of less than 300 cfm or, multiplied by 1.699, 509.7 cubic meters per hour. However, it is not always clear under which conditions manufacturers measured these values. The actual air circulation may well be less, depending on the room conditions. But if you want to heat a small room, you do not need the big two-motor device; one motor is quite enough. An airflow of at least 100, preferably more than 150 cfm is recommended. If there is a recommendation for room size in the product description, it is advisable to follow it.

Dimensions and weight

The size and weight of the stove fans hold few surprises. Most models have a height of 5 to 10 inches (12 to 25cm) and a similar width. Occasionally, there are taller versions, such as Mitsuri‘s oven fan at 12 inches (31cm), as well as products that are more in width. The latter include two-motor furnace fans, which are positioned side by side.

Depending on the model, the weight is between 500 and 1,000g. Some products also weigh less, for example, the fireplace fan from Carlo Milano with 471g. Thanks to their light weight and compact dimensions, stove fans can be easily carried to the place of use and easily stored afterwards. Neither the dimensions nor the weight are essential for buying the right device. Just make sure that they have enough space on the stove to put the device.

Handling a stove fan safely

Stove fans are simple devices: They do not contain complicated electrical components and have low maintenance requirements. You only need to wipe the case and blades with a damp cloth if they gather lot of dust and grime. As long as you pay attention to a few little things, the risk of injury is also low. Do not place the fan on an unprotected surface of the stove. The fan must not come into contact with open fire. Instead, it should be placed on a flat surface near the stovepipe. The distance from the tube should be at least 4 inches (10cm), because it is the hottest part of the furnace and temperatures of more than 662°F (350°C) are not uncommon there.

When manoeuvring the stove fan, it is advisable to wear heat-resistant gloves to avoid burns. After all, after use, the oven and the device remain hot for some time. If the bimetallic strip, which serves as overheating protection, is in use, it is recommended to reduce the oven temperature. The fan itself does not offer the possibility to adjust the heat.

Of course, you should keep the stove fan away from children — especially when it is still hot. Even if the device has cooled down after use, it is not suitable as a child’s toy. The little ones can hurt themselves on the sharp corners or damage the fan. Pets are also best kept away from it.

Image 1: © FinalCheck | Image 2: © oksana_bondar / stock.adobe.com | Image 3: © brizmaker / stock.adobe.com

3,248 reviews

3,248 reviews