Plunge saw purchasing advice: how to choose the right product

- What You Need to Know

- Plunge saws are a special type of hand-held circular saw with an immovable protective bonnet that completely surrounds the saw blade.

- They saw in the middle of the materials and not from the edge towards the centre.

- A good guide rail is important for clean and precise cuts.

- For sawing different materials, a powerful motor and a finely adjustable speed setting are recommended.

For special sawing jobs

There is a huge range of electric saws available for home and craftspeople to work with. They differ in size, shape and mode of operation and are therefore suitable for different tasks. For beginners in particular, it is very difficult to keep an overview, especially if the tasks overlap. A specialist for all kinds of cut-outs is the plunge-cut saw.

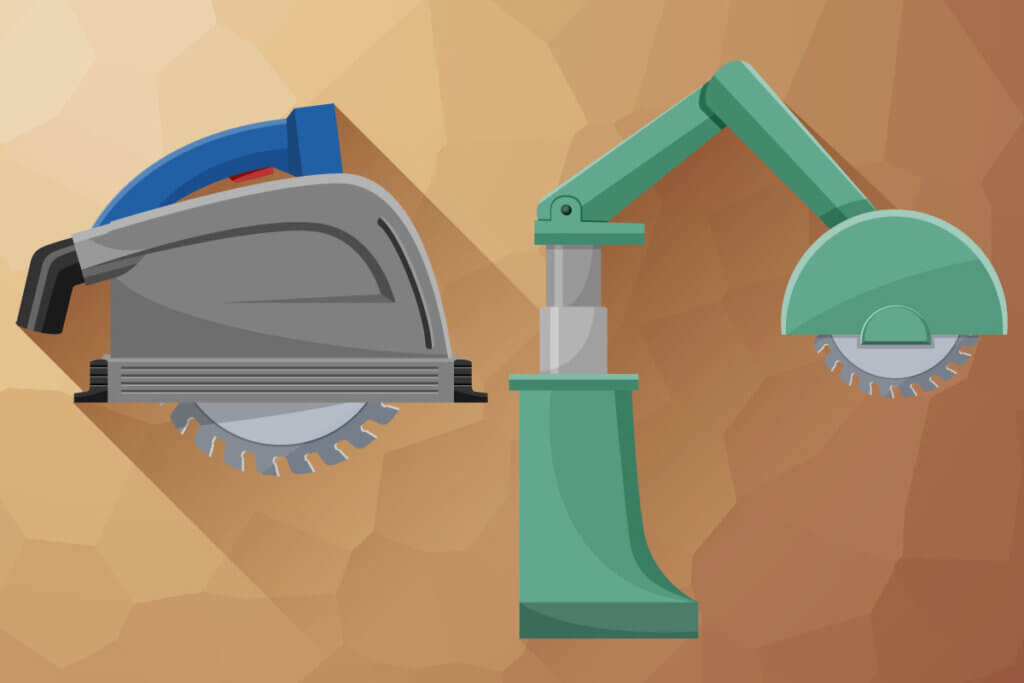

Plunge saws and hand-held circular saws

Plunge saws are a special form of hand-held circular saws. Both tools have an electric motor, a saw blade, a switch and usually a guide plate. In classic circular hand saws, the motor, saw blade and guide rail are firmly connected to each other. Since the saw blade is protected by a pendulum bonnet, the devices are also known as pendulum hood saws. They can only cut inwards from the edge of a material. While the device is making a cut, the bonnet folds away to the rear. This protects the leading hand from possible splinters. After work, the hand-held circular saw can only be stored on its side.

Unlike pendulum hood saws, the guide rail of plunge-cut saws is not connected to the motor and saw blade. Furthermore, the protective bonnet is not movable, but completely surrounds the saw blade so that it is not visible when not in use. To make a cut, the saw blade moves downwards and plunges directly into the material. Often a riving knife prevents the saw blade from jamming after the cut. The plunge cut can be made at any point of the material; it is not necessary to start at the edge as with classic hand-held circular saws.

Range of application

Plunge saws are ideal for making precise cuts in the middle of workpieces. A typical area of application is the worktop in the kitchen: the saw can be used to make cuts for the sink and hob. It is also suitable for fitting ventilation grilles.

Since the saw blade on many plunge-cut saws is positioned far to the outer right, work close to the edge is possible. You can sometimes saw up to 1.5 centimetres away from the edge. This enables craftsmen, among other things, to lay OSB or chipboard in a room and apply clean expansion joints at a later time. Another possible application is so-called shadow joints. These are the area between two building elements that are positioned offset to each other, for example wall and ceiling panelling or two frame components.

If a plunge-cut saw with a swivelling device is used, angled cuts can also be made. With such mitre cuts, corner joints between two components can be realised. A common application is the production of picture frames.

What to look for when buying

When choosing the right plunge-cut saw, the most important factors are the type and thickness of the materials you want to cut and the area of application. If you only work with the tool occasionally, you can sometimes do without some functions and save money. However, some aspects are relevant for all user groups.

Guide rail

To make precise and clean cuts, a guide rail is very important. It stabilises the saw blade and ensures that there are no tears on the cutting edge. It also serves as an anti-tip device when cutting at an angle. In contrast to classic hand-held circular saws, however, it is not essential for making cut-outs. For this reason, the delivery of plunge-cut saws for do-it-yourselfers often does not include suitable guide rails. Users can buy them as accessories.

Professional plunge saws, on the other hand, usually come with a matching guide rail. This usually has a length of 1,400 millimetres. This is sufficient for one-metre-long cuts, as the bar is ideally longer than the cuts the tool should make.

The attached guide rail must not slip away or wobble. Therefore, many models have an adhesive rubber strip on the underside. Furthermore, the rails are equipped with sliding strips on the upper side that prevent the saw blade from getting caught in the workpiece. This allows the plunge saw to glide easily through the material. To ensure that the tool does not slip during sawing, you can also use screw clamps to secure the guide rail to the workpiece.

Cutting depth and angle

An important criterion of plunge-cut saws is their cutting depth, i.e. how many millimetres the saw blade can plunge into the material. The higher the value, the thicker the material the saw can cut through. If the cutting depth can be set to the millimetre, you can adjust it precisely to any material. The typical range is 0 to 75 millimetres.

With many plunge saws, the cutting angle can be precisely adjusted via an angle scale in a range from 0 to 45 degrees. High-quality models even manage larger ranges such as -1 to +47 degrees. The negative angle allows users to make undercuts. Note that the maximum cutting depth is reduced when sawing at an angle: Instead of 75 millimetres, the saw then sometimes only dips 55 millimetres. If you often want to saw at an angle, the cutting depth of the saw should ideally be high.

Engine power

The motor power is an indicator of how powerful a plunge-cut saw is. The higher the motor power, the more likely the saw is to be able to make clean cuts in thick or hard materials. Professional plunge saws can have a motor power of more than 2,000 watts. For home use, it makes sense for the tool to have a power rating of at least 1,000 watts, preferably between 1,200 and 1,600 watts.

Speed and circumferential speed

Both the speed and the circumferential speed indicate how efficiently the exchange saw saws through different materials. The higher the values, the more powerful the saw usually is and the harder the materials to be cut may be. However, many dealers only specify the idle speed or maximum speed. The value indicates how often the plunge-cut saw rotates within one minute without load. As soon as a saw blade is attached to the machine, the speed decreases. Immersion in the material also slows down the saw. The data in the product descriptions cannot therefore be transferred to practice.

The peripheral speed or cutting speed describes how fast the saw blade rotates on the outer edge. It is directly related to the number of revolutions, but is not usually included in product descriptions.

The actual power of the plunge-cut saw can only be determined by including the torque, which requires knowledge of the gearbox. However, if you compare the circumferential speed and motor power of two plunge saws, you can at least determine the more powerful model of the two: an identical motor power at different speeds and a dissimilar motor power at the same speed indicate which model is more powerful. The cutting speed can be easily calculated using the speed in revolutions per minute and the diameter of the saw blade in millimetres. Since the speed is given in metres per second, you have to divide the resulting value by 60,000.

Calculate the cutting speed

V(u) = Pi (3.14) * diameter d * speed m

If, for example, you enter a saw blade diameter of 254 millimetres and a speed of 4,500 revolutions per minute into the formula, it follows:

V(u) = (3.14159 * 254 millimetres *4,500 revolutions per minute) / 60,000

V(u) = 59.84 millimetres per second

Practical features

To reduce the risk of injury when sawing, most plunge-cut saws are equipped with kickback protection as well as overload protection.

Since materials such as soft and solid wood, metals or various plastics have different properties, they cannot be processed in the same way: The softer and more heat-sensitive the material, the lower the cutting speed or the rotational speed should be. For cuts in different materials, it is therefore very practical if the speed can be adjusted in several stages. Otherwise, the plunge-cut saw can damage the workpiece.

If a reciprocating saw also has a constant speed function, the set speed does not change even under load. Without this feature, the number of revolutions decreases briefly in moments such as when hitting the material. With a speed control and constant speed function, it is possible to machine any material consistently at the optimum speed.

Other helpful functions are the soft start and the scribing mode. The former ensures that the motor does not immediately operate at full load when starting. With the scribing mode, the motor runs particularly stably: when plunging into the material, a clean cut can thus be made.

In addition, many modern plunge-cut saws are equipped with a system that makes it easy to change the saw blades. In simple versions, a lever must be operated for this purpose. To remove any dirt and wood chips that occur and to keep the workplace clean, plunge saws with a hoover connection are useful. You can connect a hoover hose or a dust container and suck up the dirt directly while working.

Power supply

Plunge saws are electric devices that are powered either by mains electricity or rechargeable batteries. Both types are easy to use and, depending on the model, similarly powerful. The biggest difference between the two types of drive is flexibility. With corded plunge saws, work can be done without interruptions, but users cannot move around freely. They are dependent on a nearby power socket and a sufficiently long cable. Outdoor use is only feasible with a construction of extension cables.

With cordless tools, exactly the opposite problem arises: it is possible to saw flexibly at any location. However, longer interruptions to work are sometimes necessary if the battery is flat and no spare battery is available. In addition, not every plunge-cut saw comes with a battery. Some manufacturers, such as Einhell, use a rechargeable battery system. If you own several cordless tools from such a manufacturer, you can easily swap the batteries.

Saw blades

Saw blades for plunge-cut saws are round and have cutting teeth that are placed at a certain angle. Saw blades are distinguished by their diameter, the number and shape of the saw teeth and the angle at which they are arranged.

The more cutting teeth a saw blade has, the cleaner the cut. However, this also means that the chip chamber is smaller. This is a recess between the teeth through which the chips can escape when sawing wood. If not all the chips can fall out, there is more friction between the tool and the material, which accelerates wear.

Cutting along the grain of the wood produces long chips, while sawing across the grain produces short chips. For the former, saw blades with few cutting teeth and large wood chambers are recommended, as these chips can quickly clog smaller chambers. If you are cutting across the grain of the wood, choose a saw blade with the smallest possible chip spaces and many teeth to keep the tear-out as small as possible.

The cutting teeth of the saw blades are inclined either forwards or backwards. A forward inclination is called a positive rake angle: The greater the angle, the faster the saw blade works and the greater the chip breakout. With a negative rake angle, the teeth are inclined backwards at a shallow angle. They are often used for workpieces made of steel, aluminium and building materials.

Which saw blades you need depends on the materials you want to work with. For do-it-yourselfers who work mainly with wood, however, a universal saw blade and a wood saw blade are usually sufficient. For metal or abrasive materials such as sandstone, special saw blades are recommended.

Cutting tooth shapes

The two most common cutting tooth shapes are alternate and flat teeth. For special requirements, there are also some special shapes and combinations such as trapezoidal teeth and trapezoidal flat teeth.

In saw blades with alternate teeth, the individual cutting teeth are bevelled alternately on the left or right side. They are ideal for fast cuts in all types of wood materials. On saw blades with flat teeth, the top of the teeth is completely flat. This means they cut more slowly than those with interchangeable teeth, but the cutting edge is cleaner. In addition, the robust toothing also allows hard materials such as steel to be machined.

Flat teeth with alternating chamfer have slightly bevelled edges on either the left or right side. They are also arranged alternately. This variant relieves the individual teeth and ensures a uniform cutting quality.

A trapezoid tooth is basically a flat tooth with bevelled edges on both sides. This shape is often used when sawing aluminium and hard plastics Saw blades with trapezoidal flat teeth are designed to alternate flat and trapezoidal cutting teeth.

Other accessories

To make mitre cuts easier, you can attach an angle stop to the guide rail. With the help of a scale, this can be precisely set to the desired cutting angle.

Guide rail connectors are ideal for all large-scale work with the plunge-cut saw. Instead of buying an expensive, long guide rail, they can be used to connect two short rails. The connectors are screwed to the rails in such a way that they do not interfere with the exchange saw during operation.

Some plunge saws come with a storage case so that the tool and accessories are safely stored in one place. The entire contents cannot be damaged by dirt and moisture. If a storage case is not included, it makes sense to buy one separately.

847 reviews

847 reviews